Background

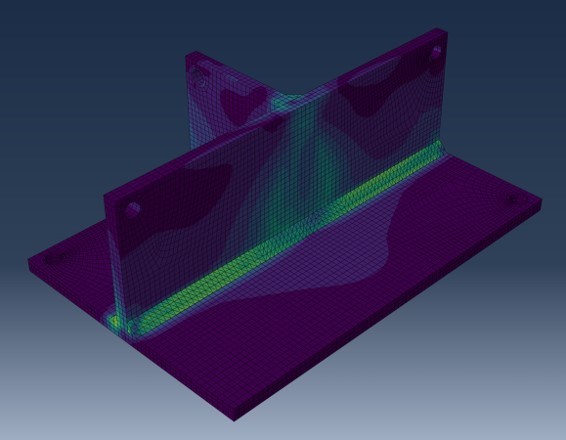

Figure 1: Physics-based modeling result showing residual stress profiles across the test part.

The fabricated structures community looks toward automation to improve the relationship between how a structure is made and how it will perform. Robotics and automation bolster the stability of the fabrication because of consistent heat input and process control. There has been significant investment in the fabricated structures and Department of Defense (DoD) circles to use physics-based simulation process modeling (particularly for high-strength steels) and to understand the impact of thermal-mechanical processes (e.g., welding or heat treatment) on the final material performance of an intended application. Weld sequence optimization processes have been developed using these simulation tools to further leverage the efficient nature of these processes.

Recent developments in machine learning (ML) and artificial intelligence (AI) enable the system to identify any variation of a part and update the welding plan in near real-time relative to that part’s condition. This new learning-based approach works at a timescale that allows new sequences to optimize for distortion and residual stress. Typical physics-based simulations are complex, time consuming, and unable to run at a rate that could support production. Leveraging these advanced learning tools enables more effective handling of the varying conditions that occur in manufacturing environments, improved operational efficiencies, and optimized fabricated products.

Figure 2: Physical test specimen with randomized input variation in the form of gaps and skew in mating plates.

Approach

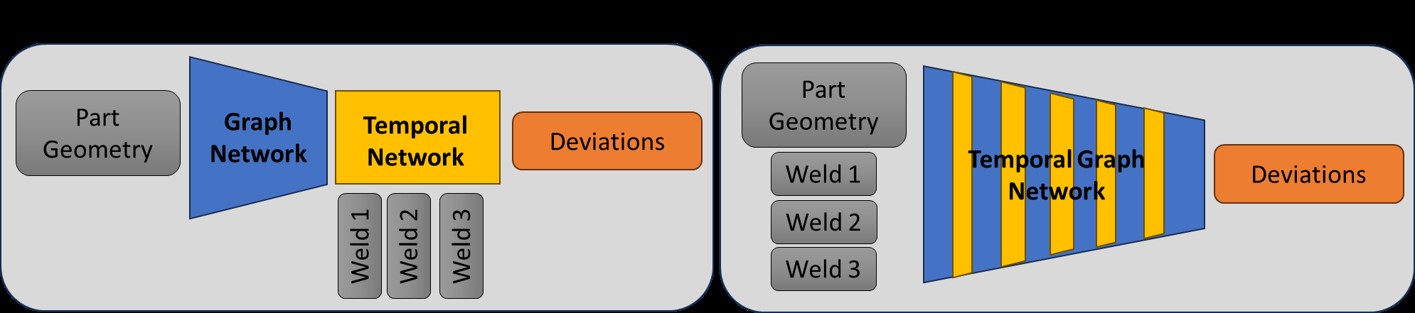

The objective of this research is to evaluate the impact of incorporating physics-based simulation modeling with a spatiotemporal graph-based ML framework. This approach will be tested by experimentation based on a U.S. Navy use case. Upon successful completion, the system will be able to recommend a welding sequence for the as-presented weldment condition. The result will be a sequence that optimizes or minimizes geometrical distortion relative to critical feature tolerances and forecasts the residual stress imparted on the structure based on the inclusion of the physics-based modeling.

Physical test data, through physical weld completion and subsequent measuring, is generated from sample test structures, where the variation of the as-presented weldments (which differs from computer aided design [CAD]) is factored into the weld sequence optimization update. The final experiment will use arbitrarily presented naval representative sub-structures with typical, random assembly variation and have the system leverage the learning framework to generate and execute a welding sequence. The resultant samples will be dimensionally compared to a naïve sequence to document performance improvement relative to distortion, while validation of residual stress will be conducted through physical measurements.

Figure 3: Updated model architecture blending a graph and temporal network.

Accomplishments

Physics-based simulations for a range of welding sequences have been successfully completed, resulting in 56 high quality training examples with a dense representation of post-weld deviation and residual stress. Additionally, experimental welding samples were collected and processed through a robust preprocessing pipeline to facilitate training the ML model from multiple data sources. This processing involved quantitatively measuring the post-weld deviation via metrology sensors and formatting the results into a similar representation as the simulated data to enable smooth transfer learning.

The model architecture has also undergone significant refinement, leading to a novel spatio-temporal network that allows for learning rich patterns in the welding process while being highly data efficient. Training and evaluation of this model on the simulated dataset has shown promising results with 4.2% error in residual stress predictions and 5.2% error when predicting displacements. These results also displayed strong generalization, with predictions on held-out weld sequences having similar error rates to those in the training set and no degradation in predictions in regions with high stress. This work is now focused on fine-tuning the current model on the experimental samples and running confirming experiments to calculated final performance metrics.