Background

Emissions regulations will soon become more stringent for mobile applications in most countries worldwide; consequently, the aftertreatment systems must become larger and increasingly complex. In particular, the state of the art in reducing nitrogen oxides (NOx) and particulate matter (PM) from diesel engine exhaust is to use two separate systems, the selective catalytic reduction (SCR) catalyst and the diesel particulate filter (DPF). This traditional approach affords satisfactory control of regulated emissions, but with added cost and size to meet the respective upcoming regulations.

The DPF can be improved by adding catalyst to the filter to provide for soot oxidation at a lower temperature during the filter regeneration process. Platinum group metals (PGM) are typically used as the catalyst and this combination is known as a catalyzed soot filter (CSF). The SCR functions by using injected ammonia (NH3) to reduce NOx. It must remain separately housed from the CSF because the PGM oxidizes NH3 thereby reducing the ammonia available to the SCR.

Another current approach to reduce system size and increase NOx conversion performance is to combine the SCR with a non-catalyzed DPF, termed an SCR on Filter (SCRoF). The SCRoF is increasing in popularity, not only because of a reduction in total catalyst volume, but also because this configuration places the SCR catalyst closer to the engine for improved cold start NOX conversion performance. The disadvantage of this approach is that it reduces the independent functionality of the catalysts and represents a compromise between soot oxidation and NOX reduction.

Approach

21 catalysts were prepared and tested for NO conversion with NH3, NO oxidation and NH3 oxidation. The catalysts were characterized to ensure the synthesis process produced a well-dispersed, well-mixed catalyst. The final formulations were washcoated and loaded with soot using SwRI’s Exhaust Gas Composition Transitory Operation Lab™ (ECTO-Lab™). The soot loaded sample showed soot removal via the NO oxidation pathway as desired.

A perovskite catalyst was also prepared and tested. Perovskites are a crystallographic framework that allows different elements to be incorporated. This flexibility has attracted attention for their use as catalysts. In this case, a La0.5Co0.375Al0.125O3 was made and tested. The selectivity to NO oxidation over NH3 oxidation was too poor to be used for the project’s primary purpose, but the activity towards NO oxidation approached, and by some measures surpassed, the PGM control sample. This highlights a possible route to reduce PGM in aftertreatment systems.

Accomplishments

This internal research project has shown that some mixed metal oxides provide for low temperature PM oxidation and high NH3 selectivity to NOx reduction instead of NH3 oxidation. In particular 0.5% Fe on Ce₀.₈Zr₀.₂O₂ and 0.5% Fe on Ce₀.₇₅Pr₀.₂₅O₂ were discovered to be excellent candidates for a novel approach developing a combined CSF/SCR. The right combination of mixed metal oxides and optimizing their placement within the flow-through substrate can reduce both volume and cost while increasing overall system efficiency.

This work will continue to be promoted to clients. It has already been presented at CLEERS, and the AC2AT-II consortium. Data and conclusions from the project have been added to multiple proposals. A provisional patent has also been filed protecting the formulations and wash coating techniques developed.

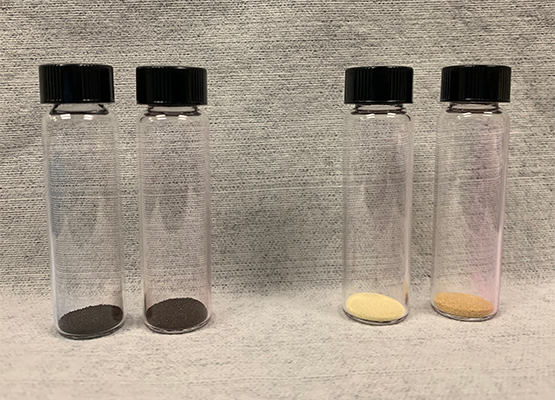

Figure 1: Catalyst Powders

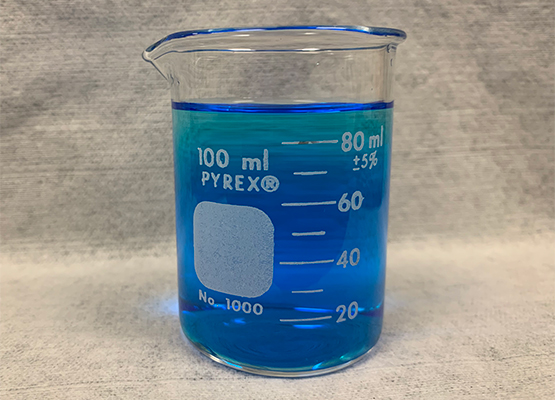

Figure 2: Catalyst Solution Production

Patents/Publications

Technical Paper – SAE 2021-24-0071

Presentation – SAENA ICE 2021 Conference, Capri, IT

Presentation – CLEERS 2020 Conference

Patent Application – US Patent Application 17/163352