Background

Oxy-fuel combustion is the process of combusting a fuel with pure oxygen as the oxidizer instead of air. This technology concept can be used for steam power cycles as well as supercritical carbon dioxide (sCO2) power cycles. In either cycle, the combustion takes place within the steam or sCO2 working fluid. In sCO2 applications, the oxy-combustion process generates carbon monoxide and a large amount of water, which must be separated and removed from the close-loop cycle so as not to affect the performance of other components and to maintain a high purity sCO2 fluid.

Because oxy-combustion in sCO2 can use methane as a fuel, the combustion products of CO and H2O are not unlike those of steam methane reforming, which is a process to convert methane to hydrogen. The advantage for sCO2, however, is that it is a power generating cycle and hydrogen is a byproduct, whereas steam methane reforming is its own process that must be paired with a power cycle to generate both hydrogen and power.

Approach

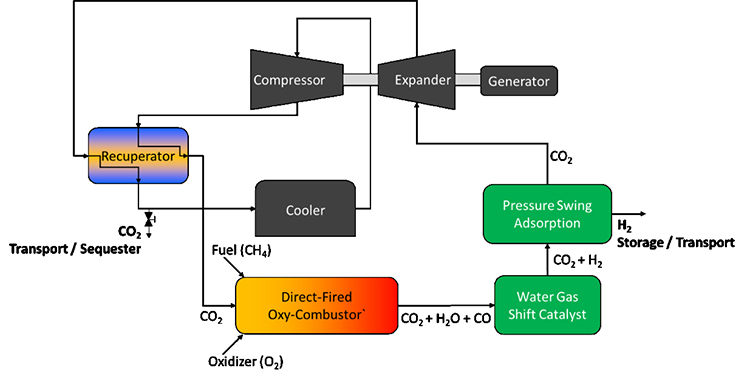

In this project, a model was developed to study the performance of a novel direct-fired sCO2 power cycle (Figure 1) with additional components to convert combustion products to pure hydrogen that can be used as a fuel. These components, similar to steam methane reforming, are a water-gas shift reaction (WGSR) and a pressure swing adsorption (PSA) process. When compared to a state-of-the-art SMR (Lozza & Chiesa, Journal of Engineering for Gas Turbines and Power, 2002), the model predicts that the novel cycle will use less CH4 and will have significantly higher efficiency, while producing high-pressure H2.

Figure 1: Novel sCO2 power cycle that removes H2O and CO while producing H2.

Accomplishments

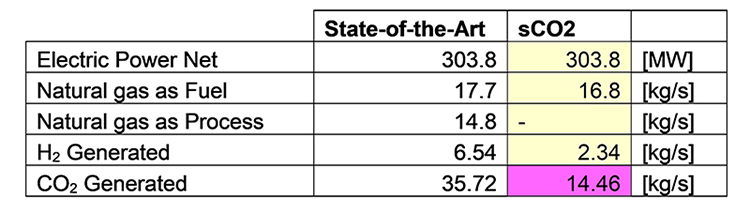

The results of the new approach can be seen in Table 1. In the comparative state-of-the-art cycle, a total of 6.54 kg/s and 35.7 kg/s of H2 and CO2 are generated with a net power output of 303.8MWel. The overall natural gas required for the cycle is 32.5 kg/s with 14.8 kg/s being used for the SMR to generate H2. In comparison to the novel sCO2 cycle developed in this project, significantly less natural gas is needed, The CO2 production has been more than halved, and much of the HRSG and SMR hardware has been eliminated. The amount of H2 being generated is significantly less in the sCO2 cycle, but the net benefits are significant.

Table 1: Novel cycle performance.