Background

Supercritical carbon dioxide (sCO2) power cycles offer a potential pathway to increase the efficiency and decrease the costs of power generation. These power cycles offer efficiencies significantly higher than achievable with the incumbent steam power cycles. At the same time many of the components, especially the turbomachinery, are much smaller than a steam power cycle with comparable power output.

Direct-fired sCO2 cycles allow for higher cycle temperature, and thus higher cycle efficiencies. This is a necessary feature of the cycles to allow for high efficiency while also capturing 100% of the produced carbon dioxide. These power cycles operate at elevated pressures not typically seen in other combustion systems, thus making experimentation more difficult. Very few experimental measurements have been conducted in direct-fired sCO2 power cycles. The lack of experimental data to support computational models is currently hampering the development of this technology. This project seeks to provide some of the necessary experimental data to promote further research and development of this exciting technology.

Approach

Computational modeling necessary to design sCO2 combustion systems currently suffers from a severe lack of validation data. While limited validation experiments in shock tubes at premixed conditions have been conducted in the last few years, no data for realistic non-premixed conditions exists in the open literature. The objectives of this project are to:

- Develop non-intrusive measurement techniques for use in a direct-fired oxy-fuel combustor for sCO2 applications.

- Use these techniques to generate realistic sCO2 power generation validation data in a simplified combustor geometry.

- Validate computational fluid dynamic (CFD) simulations using the acquired experimental data.

If successful, the proposed research should advance national capabilities for the development of sCO2 power cycles for emission-free electricity generation. Specifically, it is anticipated that upon completion of this project multiple state-of-the-art non-intrusive optical diagnostic techniques will be matured and demonstrated in laboratory bench-top testing at UTSA and in a combusting sCO2 test rig at SwRI. Qualitative flow visualization of the reacting flow will be captured, as well as data on soot formation, flow velocity, and concentration of reaction products.

Accomplishments

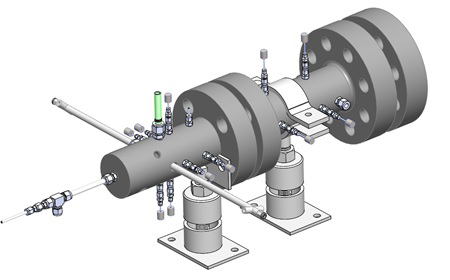

SwRI has developed a small bench top combustor system. This project will use optical techniques to examine the combustion processes of the combustor. The combustor uses a non-premixed coaxial injector to produce combustion in an sCO2 dilution environment. The current combustor design, seen below in Figure 1, is intended for low inlet temperatures below 250°C. The combustor instrumentation for this experiment consists of thermocouples and dynamic pressure sensors, and this project will add optical access and measurements to the combustor.

The optical probe, which will allow detailed diagnostics access, is shown in Figure 2. The probe’s sapphire window installed in the front of the probe proved to be difficult to seal. After several different attempts were made of setting the window into the probe and fixing it with epoxy, a methodology was found that allowed for the probe to successfully pass a hydrostatic test. The probe is currently ready to allow viewing into the combustor at the 200 bar and the elevated combustion temperature.

Figure 1: CAD model of bench top combustor test stand.

Figure 2: Optical probe, note discoloration after heat treatment to set epoxy.