As the drive for cleaner, more efficient vehicles continues, Southwest Research Institute remains on the vanguard. Combining our expertise in powertrain technology with our longstanding fuels and lubricants research allows SwRI to provide innovative solutions to automotive challenges from headlights to tailpipes.

Our San Antonio headquarters offers one of the largest independent engine, fuels and lubricants research facilities in the world, and we test virtually every engine oil and fluid available on the market. SwRI now offers engine development facilities in Ann Arbor, Michigan, augmenting more than 200 research dynamometers at our headquarters. In addition to expanding our capabilities in high-efficiency powertrain development and emissions research, these facilities provide local resources in the Detroit area.

Courtesy of A&D Technology, Inc.

Ann Arbor, Michigan

We have expanded our automotive research footprint in Ann Arbor, Michigan, to offer Detroit-area clients convenient local resources for powertrain control and emissions research.

Collapsible Tank Testing

We tested a 50,000-gallon collapsible tank filled with aviation fuel. Our double-lined tank farm can accommodate collapsible tanks that hold up to 210,000 gallons.

To support next-generation engine technology, we have designed single-cylinder research engines to study everything from knock and combustion stability to real-time wear under challenging operating conditions. These research engines are available for purchase, and we have three variations available in our labs, two for light- and medium-duty applications and one for heavy-duty applications. These research engines can be configured for spark- or compression-ignition research for alternative fuel, wear, optical, crank offset and bore-to-stroke relationship studies. The custom design accommodates multi-cylinder or single-cylinder heads. Unique patent-pending features include mechanisms to adjust compression ratio and crankshaft offset without engine disassembly.

This year, we doubled the capacity of our Exhaust Composition Transient Operation Laboratory while expanding catalyst and aftertreatment research capabilities. Additions include an automated universal synthetic gas reactor to test catalyst core samples and three systems for accelerated aging and evaluation of emission control system performance.

To support the growing electric and hybrid vehicle market, our Energy Storage Technology Center is moving into new facilities. With the additional space, we will expand our battery research, develop new energy storage and management systems, and increase evaluation capacity for lithium ion, advanced lead acid and ultracapacitors for automotive, consumer products and grid storage systems.

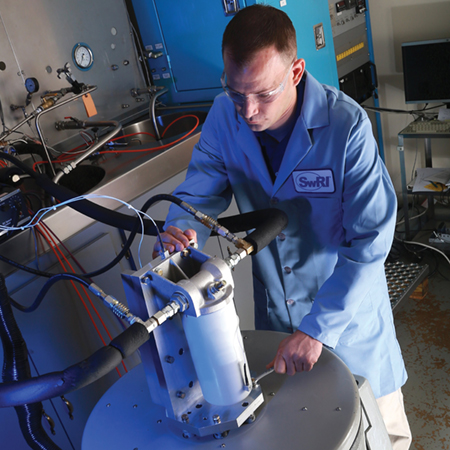

Evaluating Fuel Filters

We developed a procedure to evaluate diesel fuel filters under cyclic fluid flow rates and controlled structural vibration. This method simulates actual service conditions better than traditional filter efficiency tests.

Engine Damage

To understand ring liner scuffing in engines, our tribologists extract lubricant from different regions of the piston assembly to determine what processes cause the damage.

Dynamometer Studies

SwRI conducts 100,000-mile engine dynamometer studies for electric vehicles. Every 10,000 miles, we evaluate how aging affects battery range, pack performance, pulse power and charging strategies.

For the U.S. Department of Energy, we are integrating connected and automated vehicle technologies with the goal of improving the energy efficiency of a hybrid vehicle by more than 20 percent. We are using connected vehicle technologies to “preview” roadways and optimize route, speed profile, and power flows from the hybrid system. The project will ultimately help define future powertrain performance requirements.

SwRI also has developed high-horsepower off-road dual-fuel engines that easily meet the Environmental Protection Agency’s prior Tier 2 regulations. More recently, SwRI engineers demonstrated how dual-fuel engine designs could potentially meet the latest Tier 4f regulations without the need for catalysts, exhaust gas recirculation or particulate filters. These technologies not only add to the initial cost of the vehicles but also can increase fuel consumption, reduce engine performance, and add operational and maintenance costs. The goal was to design and demonstrate a dual-fuel engine that meets Tier 4f without active aftertreatment systems.

In other large engine work, SwRI operates a locomotive technology center near downtown San Antonio, where engineers are testing new locomotive engines for exhaust emissions compliance. We are also evaluating “end of useful life” exhaust emissions, testing engines just before they are overhauled to determine if locomotives meet applicable EPA emissions standards throughout their service life.

In addition, we are developing tests to evaluate automotive engine oils to the International Lubricants Standardization and Approval Committee’s GF-6 performance specifications. Oils meeting the specification should increase fuel economy, enhance oil robustness and reduce engine aeration. Our researchers led the development of a new engine oil oxidation test and helped define specifications for new fuel economy and low speed pre-ignition tests.

Through internal funding, SwRI tribologists are developing a screening technique to better understand scuffing between a piston ring face and cylinder liner in engines. The technique will evaluate how lubricant chemistry, viscosity and frictional response affect this unpredictable, hard-to-reproduce phenomenon. We also designed a novel high-frequency reciprocating rig to evaluate the lubricity of highly volatile fuels such as gasoline, liquefied petroleum gas and dimethyl ether.

Recently, we developed a method to map dynamic performance of elastomer O-ring seals in real time and built a dynamic seal tester to investigate how fuels and lubricants affect elastomer seals in operating environments. For the U.S. Army, we are developing concepts for a federal test method to compare the performance of fuel lubricity additives.

For the past 60 years, SwRI has operated the U.S. Army Tank Automotive Research, Development and Engineering Center (TARDEC) Fuels and Lubricants Research Facility. Located at SwRI, TARDEC is a government-owned facility providing advanced research, development and engineering services to the U.S. Army and other agencies. In 2017, engineers evaluated a 50,000-gallon collapsible fuel tank filled with aviation fuel at a new SwRI tank farm. These portable tanks, which range from 3,000 to 210,000 gallons, store fuel for military field operations. Qualification testing previously used water as the testing medium because a safe and environmentally secure facility to test with fuel was unavailable. Now, our dedicated, double-lined tank farm, which accommodates tanks of all sizes, allows SwRI to perform qualification testing using fuel.

In 2017, we established a new method to evaluate diesel fuel filter performance under real-world conditions. Diesel fuel filters mounted to engines or other machinery typically experience vibration and variable fuel flow. Using cyclic fluid flow rates and controlled structural vibration, this new method not only evaluates the filters but also demonstrates how dynamic events affect performance.

SwRI is a leader in developing and managing consortia that allow clients to pool their resources for pre-competitive research. Eight automotive consortia are currently active. Our Clean High-Efficiency Diesel Engine consortium has been making diesel engines cleaner for more than a quarter of a century and recently developed a modular heavy-duty single-cylinder engine to support research activities. Our High-Efficiency Dilute Gasoline Engine consortium has spent more than a decade pursuing lower emissions and higher fuel efficiency. The Advanced Engine Fluids group studies how fuel and lubricant chemistry affect engine durability and performance, while the Advanced Combustion Catalyst and Aftertreatment Technology consortium focuses on emission control technologies. The Aluminum Head Evaluation, Analysis and Durability consortium is developing lighter, more durable engine components to help meet tighter fuel economy and emissions regulations.

For more information visit Automotive & Transportation or contact Vice President Daniel W. Stewart, P.E., +1 210 522 3657 or Vice President Steven D. Marty, P.E., +1 210 522 5929.