SwRI picked up two “Oscars of Innovation,” R&D 100 Awards, in the 2025 R&D World Magazine competition. The R&D 100 Awards recognize the most significant technical accomplishments of the year. The prestigious award has honored top tier, revolutionary science and technology for more than 60 years. SwRI was recognized as co-developer on two winning projects, the Copeland Oil-Free Centrifugal Compressor and the Low Mass High Efficiency Medium-Duty Truck Engine. This year, the competition drew entries from 13 countries and regions. SwRI has won 54 R&D 100 Awards since 1971.

Listen now as SwRI engineers Dr. Jason Wilkes and Ryan Williams discuss what makes these technologies stand out as innovations of the year and how SwRI’s expertise contributed to the development of the award-winning compressor and engine.

Visit Honors and Awards to learn about SwRI’s R&D 100 history.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña:We're highlighting two technologies recognized as the most significant innovations of the year and winners of 2025 R&D 100 Awards, known as the Oscars of innovation. The prestigious award honors top-tier, revolutionary science and technology. And the Oscar of innovation goes to... the big reveal next, on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now, let's understand it better. You're listening to the Technology Today Podcast presented by Southwest Research Institute. From deep sea to deep space, we develop solutions to benefit humankind. Transcript and photos for this episode and all episodes are available at podcast.swri.org. Share the podcast and hit that subscribe button on your favorite podcast platform.

Hello, and welcome to Technology Today. I'm Lisa Peña. The R&D 100 awards, known as the Oscars of innovation, presented by R&D World Magazine, have recognized outstanding science and technology for more than 60 years. In 2025, the competition drew entries from 13 countries and regions. Since 1971, Southwest Research Institute has won 54 R&D 100 awards.

This year, SwRI was involved in the development of two winning technologies. Today, we're discussing an engine for medium-duty trucks that yields a 10% increase in fuel economy. We'll talk about what sets it apart and SwRI's role in development. But we'll start this episode with the Copeland Oil-free Centrifugal Compressor with Aero-lift Bearing Technology. SwRI Engineer and senior manager, Jason Wilkes, joins us now to tell us what makes this compressor one of the most significant innovations of the year. Thank you for being here, Jason.

Image

Copeland

The Copeland Oil-Free Centrifugal Compressor with Aero-lift™ Bearing Technology, co-developed by Southwest Research Institute and Copeland, was selected as one of the 100 most significant innovations of 2025 by R&D World Magazine. The compressor cools industrial spaces and large facilities while eliminating the traditional costs associated with oil maintenance and expensive magnetic bearings.

Jason Wilkes: Thank you, Lisa.

LP: So congratulations on the R&D 100 award. This is actually the second time you are a key member of a winning development team. Now, you previously won for the integrally geared supercritical CO2 compander. That was back in 2022. So how does it feel to be a two-time winner now?

JW: Feels great, Lisa. Winning the first time, obviously, made it a highlight to a long project with a large team. And even though this project happened a while ago, the notion that the project has been commercialized by our client and that they're starting to sell these units is really exciting from our side. As you know, this is an honor that the Institute puts some emphasis on. And it's certainly an honor to be selected once, and certainly twice.

LP: OK, so I want to get into the technology now. So let's start with a basic explanation of a compressor. What does a compressor do? How are they commonly used?

JW: So a compressor is used to do just that. It compresses gas. The difference between a compressor and a pump is that a compressor compresses gas and a pump, like a pool pump, pumps fluid. So in the most common compressors, like a bike pump or a pump to pump up your tire in your car. You're essentially using gas at a higher pressure because that's what's useful to you.

In the case of this compressor, this is a compressor that's used in a refrigeration application. And any time that you let pressure down across a device, a valve or something like that, it gets cold. And so in the case of a refrigeration compressor, you compress a fluid, you reject the heat from it. And then once you expand it, it becomes cold. And so that's what the refrigeration compressor in this application is used for.

LP: OK, so compressors are pretty much everywhere. But the Copeland Oil-free Centrifugal Compressor is different from traditional compressors, so what sets it apart?

JW: So this compressor is unique. Primarily in the world of refrigeration, most of the compressors in your house or mine are a positive displacement type of compressor. That's kind of like a bike pump. You take a volume and you make it smaller, and then you push gas out of that volume. So in this instance, this is for larger applications and those devices are typically a rotating machine closer to, I would say, the compressor on a gas turbine.

It's basically using centrifugal forces to increase the energy of a fluid and then turn that into pressure. You can do a much higher flow rate and a much higher power with that type of device. The traditional compressor in a chiller application is usually a centrifugal chiller, but back in the day, these machines were slow, large-diameter machines.

In the past 15 or 20 years, these machines have become higher speed, they're hermetically sealed, meaning that they don't leak any fluid out, and traditionally, they have employed some form of bearing technology like a magnetic bearing, which is a little bit more complicated and more sensitive to disruption. What makes this compressor really unique is that it's using gas bearings, which we've, historically, helped a lot of clients develop machines on gas bearings.

So this particular compressor uses a gas bearing, which has no moving parts. It operates on a film of the refrigerant itself. And so with almost zero wear and nearly infinite life, this compressor can sit there and operate at steady state conditions without accruing damage on the bearings.

LP: OK, so oil-free is in the title, the Copeland Oil-free Centrifugal Compressor. Why is this an important characteristic of this technology?

JW: Oil has been used in refrigeration systems for a long time, mainly because there was moving parts, bearings, seals, that performed better with the oil. Because this is in a closed-loop system, where you essentially compress the fluid, reject the heat, expand the fluid, then you do cooling of your atmospheric air or the water, and then you come back through your compressor.

The problem is that oil migrates throughout your system and ends up in a lot of places where it's not really desirable. So the oil ends up clogging up avenues in the cold side of your system, and it's really unfavorable. So the notion that this has zero oil in it is really advantageous to pretty much everybody that works in refrigeration systems.

LP: And so you mentioned that this operates on a film of the refrigerant. Does that film replace the oil?

JW: In this type of device, yes. It would potentially replace an oil bearing or an external seal that might have an oil in it.

LP: OK, so you touched on this a little bit, but centrifugal also in the title. What makes it centrifugal?

JW: So centrifugal compressor is a compressor that essentially throws the fluid out and then slows it down. And that's where it builds in pressure. And so very much like a fan blade on a jet engine, it uses basically a turbomachine to compress the fluid, as opposed to a positive displacement machine.

LP: OK, so the Copeland compressor uses what's called Aero-lift bearing technology. So how does Aero-lift improve the system?

JW: Aero-lift is simply a trademarked name that Copeland came up with for their gas bearings. I can't speak to the exact nature of the gas bearings that they have, but gas bearings have been around for a long time. They're used in a lot of aviation applications and small high-speed machinery. The gas bearings that we're talking about basically have a film of compressible fluid that the shaft rides on. And then underneath that fluid is some sort of spring structure that gives the bearing its damping and stiffness characteristics, and that's what supports the shaft.

LP: And I wanted to bring in Copeland. So can you tell us about their role, our role, how we collaborated on this technology?

Image

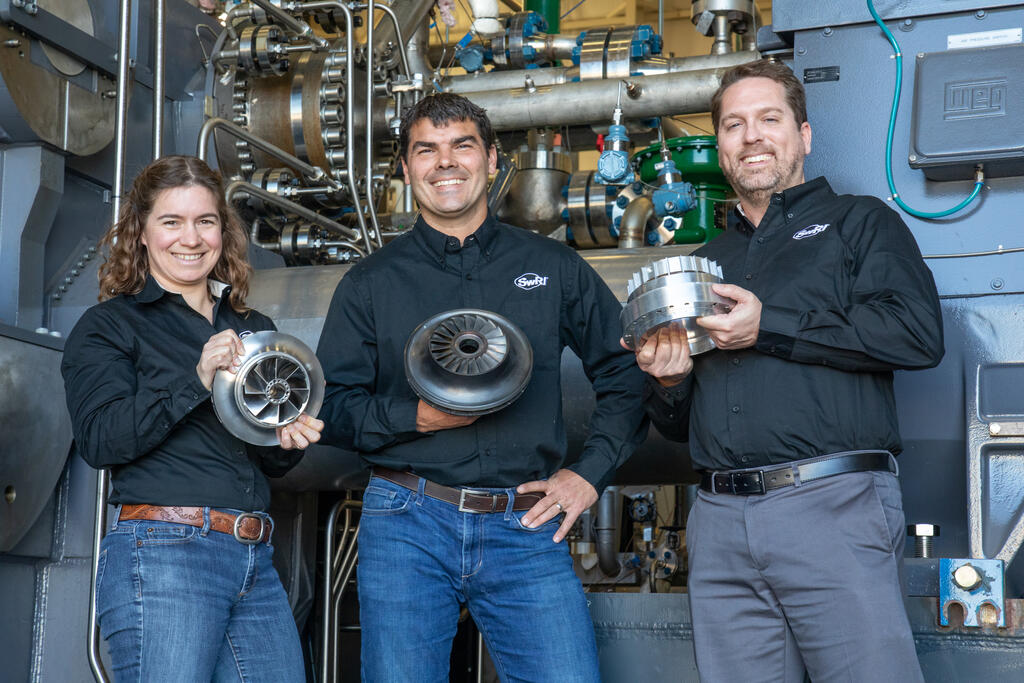

SwRI engineer and Senior Manager Dr. Jason Wilkes (center), co-developed the Copeland Oil-Free Centrifugal Compressor as part of a SwRI team. This is Wilkes’ second award-winning technology. He won an R&D 100 Award in 2022 as part of the development team for the Integrally Geared Supercritical CO2 Compander.

JW: Yeah. Copeland's been around for a long time. They're one of the largest manufacturers of compressors in the world by quantity. They make tremendous number scroll-style refrigerant compressors, which is what's in a lot of residential units. With our experience in gas bearings, Copeland came to us with an idea to develop a gas bearing refrigeration compressor.

This was one of the first gas bearing refrigeration compressors that was ever pursued. So this was Copeland driving the design space and everything else. And we brought our team to the table that had a foundation in turbomachinery design to basically do the alpha design for this machine. Since then, Copeland has been developing their own team to support the development of the machine, the manufacturing, and a lot of other critical aspects of the technology.

So they're the owners of the technology now, from both a technical and a business standpoint. They leveraged our ability and prototype machinery to conceive of, like I said, the first generation of the design. And I think a lot of the detail that we included into our design and the trade studies are still impactful in their final product, but they're going to continue to mature this design for the next 20 and 50 years until the next thing comes along.

LP: What are some of our capabilities that make us the ideal organization to tackle this type of challenge?

JW: What makes us unique is that we have the capability to develop and have developed numerous first-of-a-kind turbomachinery designs. And really, when you're working with a compressible fluid, whether it's an organic fluid, whether it's an inert gas, whether it's a flammable mixture, there's details within that design that make it unique.

But overall, the process of designing a first-of-a-kind machinery, whether it's high temperature, low temperature, we bring that expertise to the table. And it very well could be the case that a natural gas compressor looks almost identical to a cryogenic machine. It may also mean that it doesn't.

So our ability to, I guess, work with unique design sets when or constraints when there's not an OEM or a manufacturer of original equipment like a GE or a Siemens that says, oh, I sell that machine, it helps our clients either prove first-of-a-kind applications or develop first-of-a-kind machines, in this case, where nothing exists on the market.

LP: OK, so let's talk about which industries would most benefit from using this compressor?

JW: So chillers are used all over the place to cool water that's used in any kind of industrial application. So these range from 200 tons to up to 1,000 tons. And a ton is basically how much heat you remove from a space or from a fluid. So an example system would be data centers. Everybody's talking about AI.

I hate to mention it because everybody's talking about it, but data centers consume a huge amount of power, and that power is all converted to heat inside of the data center. So how do you remove that heat? Well, you've got to dump it to something. So that may be a water system, like a conventional chilled-water system. It could also be something more advanced, where somebody's dumping it directly to refrigerant that is immersing the chips.

So I guess all of these technologies combined, where we're predicting the power load of our grid to increase significantly. Almost all of the power on the grid becomes heat. And so in industrial applications, when you're cooling a chicken and then you need to or when you're baking a chicken and then you need to freeze it, you need to add heat and then remove heat. So chillers would be an example that would be used to remove that heat in a very large industrial setting.

LP: All right, and just to connect the dots, the compressor is part of the chiller.

JW: So the compressor is the heart of the machine that creates the thermodynamic cycle that cools the fluid. So the compressor is the heart of any refrigeration machine or any heat-pump style system.

LP: OK, and in turn, the chiller would be placed in, as you mentioned an example, a data center, a big operation like that where heat would need to be removed.

JW: Correct.

LP: OK, bringing it back to SwRI. What is your next challenge? What future R&D 100 award-winning technologies do you have in the pipeline?

JW: Well, as you noted earlier, I've stepped away from technical a little bit and have moved into a managerial role in the past five years. And part of that comes with doing a little bit less technical work, but developing the next set of engineers that are going to change the world. And so my task is to make them as effective as they can in executing projects for great clients.

LP: All right. Looking forward to what your team has in store next. Jason, what do you enjoy about this work? What motivates you? When we're talking about compressors and chillers and refrigerants, to the average person, that doesn't sound super exciting, but I know you have a different perspective on this type of work. So what motivates you?

JW: I think what's fun about designing turbo machines is that there is a number of competing design constraints and between mechanical challenges, aerodynamic challenges, reliability challenges, cost, lead time, combining all of these challenges into one device, one machine is no different than any other area of engineering, but I find it very exciting because it's not clear what the best answer is.

And so it takes a large team of individuals all working at pursuing the best part of their design and being flexible with each other to design the best overall machine to a particular purpose.

LP: OK, well, congratulations to Copeland, to you and your team on this R&D 100 Award. And again, winning this prestigious award not once, but twice in three years. So truly a remarkable achievement.

JW: Thank you, Lisa.

[MUSIC PLAYING]

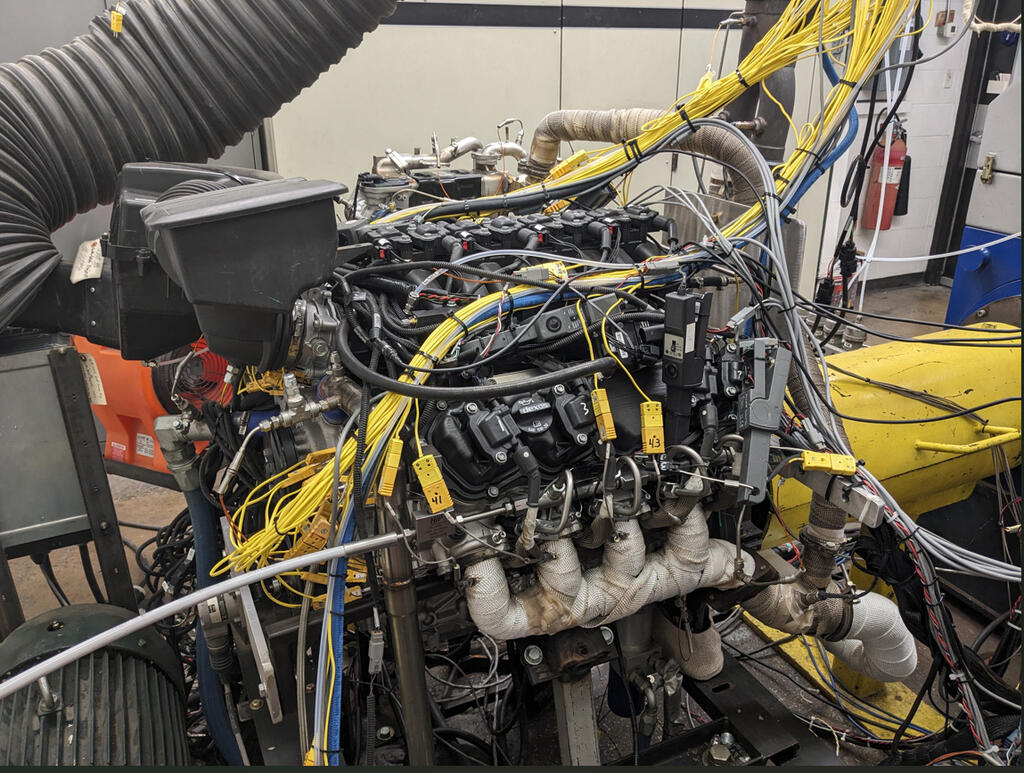

Image

The award-winning Low Mass and High Efficiency (LMHE) Medium-Duty Truck Engine yielded a 10% increase in fuel economy and a 15% weight reduction when compared to production engines using advanced materials and combustion technologies. This photo shows an engine installed in an SwRI laboratory for testing.

LP: Our next standout technology and 2025 R&D 100 Award winner is the Low Mass, High Efficiency Engine for Medium-duty Truck Applications. This project was funded by the US Department of Energy Vehicle Technology Office and led by General Motors. SwRI engineer and manager, Ryan Williams, joins us now to tell us about this exceptional engine and SwRI's role in the project. Thank you for being here, Ryan.

Ryan Williams: Thanks, Lisa. I'm happy to be here.

LP: So what does it mean for you to be part of this award-winning team that developed one of the year's 100 most significant innovations? That's a big title there.

RW: Well, like you said, this is kind of like the Oscars of innovation. And so it's great to be recognized. This project was really the culmination of four years of work in collaboration with a whole host of universities and national labs, and of course, with General Motors, kind of across the whole spectrum of the industry. So it was a great opportunity to work on this project and always great to be recognized for the work that we've done.

LP: All right, so this is an engine for medium-duty trucks, specifically. When we say medium-duty trucks, what type of vehicles are we talking about?

RW: Yeah, that's a good question, because when we talk about medium-duty in the context of the breadth of trucks, in general, we're usually talking about the lower end of things. But when we think of a lot of these trucks, this is going to be toward the higher end. So this is like the 3500 series and the 2500 series pickup trucks, but the very heavy-duty, the workhorse trucks for contractors. And a lot of times, these engines will go into things like panel vans and other food trucks and things like that.

LP: Let's talk about the Low Mass, High Efficiency Engine that won the award. What makes this a unique solution for medium-duty trucks?

RW: Like the name suggests, there's two pieces to this. There's the low mass piece of it, and the high efficiency piece of it. So the low mass was really focused on bringing down the weight of the engine. Because the application that these engines go into are so demanding, they tend to be pretty beefy engines with big cast-iron blocks and cranks that just really heavy components.

And so the low mass piece of this project was focused on bringing that down and bringing in some of the technologies from light-duty, like aluminum alloys and aluminum casting and new casting and forging techniques to help reduce the mass of the engine. And then the high efficiency side was focused more on still retaining the power and torque that these engines need to make to be effective, but using less fuel as we do that.

LP: :So more efficiency, but in a smaller package. And why is it beneficial to have that smaller package?

RW: :Mainly because the less weight we carry in an engine, the more weight capacity we have for the vehicle. And so as we reduce the overall weight of the vehicle, that uses less fuel and allows us to carry more payload.

LP: All right. So this engine's solving a couple of problems, a couple of challenges here. So how did this project start? Who was involved in the development?

RW: Yeah, so of course, General Motors was the recipient of this award from the Department of Energy. And then they pulled together a team to work on the various aspects of the project. So there was two different objectives. The weight reduction side of it had a target of reducing the mass by 15%. And then on the efficiency side, they had a target of improving the efficiency by about 10%. Once GM had an idea of what they wanted to do, then they went out and solicited for collaborators on the project.

LP: OK, and SwRI was one of those collaborators. So this project resulted in the development of several key technologies. So tell us about the innovations that resulted from this program.

RW: Yeah, so I guess to get to that, we kind of have to go back about 20 years in some of the work that we've been doing here at the Institute, specifically in our engine-focused research consortia. So we have, for a very long time, been running a consortium called the HEDGE consortium, which stands for High Efficiency Dilute Gasoline Engines. And already in that name, you hear a lot of the keywords that we're hearing from this project.

So that was focused on similarly bringing new technologies to gasoline engines to help improve efficiency. And of course, General Motors has been a longtime member of that consortium. And so we have a very long history of working with General Motors to improve the efficiency of gasoline engines. One of the technologies that came out of that consortium, specifically, is this idea of exhaust gas recirculation.

And specifically, we had a patented technology called Dedicated EGR, which coincidentally won an R&D 100 Award about 10 years ago. And the idea there is that we take a portion of the exhaust gas and we recirculate it back into the intake. And that has the effect of suppressing a phenomenon in gasoline engines called knocking. And basically knocking is when the fuel burns faster or sooner than we want it to.

Ideally, with a gasoline engine, you take your fuel and your air and you mix it all together. And just at the precise moment when you want combustion to happen, you fire your spark plug and you get this nice controlled burn. But if the conditions are too hot or we get too much pressure or temperature inside the cylinder, then some of that fuel can actually auto ignite and it causes very high pressure rises in the engine and can be very damaging to the engine.

And so the work that we've been pioneering, again, for about 20 years in this field, has been to use some of this exhaust gas recirculation to suppress knock. And that allows for higher loads, higher efficiency, and overall improved performance of engines. So when GM was putting together their plan for this 10% efficiency improvement on this engine, this exhaust gas recirculation concept was kind of core to their strategy. And so we were a natural partner to pick on this program.

LP: With the history of collaboration between GM and SwRI, again, as you said, this was a natural collaboration. So let's get into it a little deeper. What did SwRI accomplish in this project? What was our role in development?

Image

SwRI engineer and Manager Ryan Williams was part of the development team for the award-winning LMHE Medium-Duty Truck Engine. This project was funded by the U.S. Department of Energy Vehicle Technology Office and led by General Motors.

RW: So our role was mainly, once all of the design and the weight reduction had taken place, the engine was built and sent to us, where we installed it in one of our test cells. We did all of the development and the testing and the validation of this technology to collect the data set that gave the final 10% efficiency improvement. So a big piece of this was down selecting of various technologies.

We jokingly, within our group, called this the kitchen sink project because we were looking at pretty much everything but the kitchen sink for efficiency improvements. And so we looked at things like high-injection pressure. We looked at this exhaust gas recirculation. We studied some things like passive prechamber technologies and some advanced spark plugs.

And our role was to evaluate all of those technologies individually and quantify the efficiency improvements that could come from each of those. And then working with General Motors, they put together a plan to say which are the ones that are most promising and which collection of technologies will get us to the 10% improvement that we're looking for. And then once all of that was done, we put together a final engine. And that's when we did the final demonstration.

And so that involves taking the engine, putting it into a test cell, where we go through and calibrate the engine. We look at the levels of each of these technologies and kind of dial in the performance to get the exact effect that we want.

LP: OK, so you touched on this already a bit, talking about GM's role in our consortium and our long history of collaboration. So that explains why we were called in for this particular expertise, but what SwRI capabilities does this project highlight?

RW: It highlights a few things. Of course, our testing capabilities. We're one of the largest independent testing houses, outside of some of these manufacturers, for being able to test and evaluate engine performance. We have capabilities of testing very fine and detailed differences. So in many cases, with these technologies, we had to differentiate between maybe a half a percent or 1% improvement in fuel economy. And that's very hard to do. And so we've kind of perfected that over the years to be able to make very fine measurements of these engines.

The other piece of it that was really important for this program was the controls aspect, because, specifically with this exhaust gas recirculation and the dedicated EGR concept, it requires some overriding of the main engine controls. And so our control team was able to work with the control team from General Motors to integrate some of these control strategies into it to more effectively run the engine.

LP: Can you tell us about some of the equipment that we house here at SwRI that helped you achieve these milestones on this project?

RW: Yeah, I guess the heart of all of this is the engine dynamometer. And so it's basically a large electric motor that can both absorb and put power into the engine. And so this works kind of like a treadmill, I guess, for the engine. So we can run the engine. We can simulate different conditions that it would see in the vehicle, but we can measure all of that in a very controlled environment, rather than just putting this vehicle out on the road and trying to measure things in a dynamic environment.

We can take it into a test cell, where we've got very fine control on things like the measurements of the airflow and the fuel flow, and we can very precisely measure the power output of the engine. And that's what allows us to really zero in on these very minute differences between efficiency.

LP: So has work on this project with the LMHE engine resulted in advancements on other projects?

RW: I would say yes. This has worked to advance the technology, in general. Of course, like I said, this exhaust gas recirculation has been kind of a hot topic for gasoline engines for a long time. And so this was a nice way to see the culmination of a lot of work that we've done in that area, to be able to finally get it into an application and do the complete development of that application so we could see the full potential of what we can get out of this EGR concept.

LP: At SwRI, we're always working on solutions to solve the next challenge. So what is your team currently working on? Anything upcoming you can tell us about?

RW: Yeah, like I mentioned, this is a very challenging space for these vehicles because it's very demanding environments. These vehicles can have up to 36,000-pound towing capacity. And at the end of the day, our goal is to decarbonize transportation. And these medium-duty trucks, specifically, have been labeled as one of the applications that is very difficult to decarbonize.

When you think about the majority of the automotive space, we see a lot of electric cars, and those seem to be ideal applications for batteries and electricity. But now we're seeing more and more of these electric pickup trucks get into the market. And they're not meeting the demands of the customers. And so we've got to find other solutions, like improving efficiency and decreasing the weight.

And the next frontier for that is hybridization. And so we're working on optimizing the architecture of these hybrid systems. A lot of the hybrid systems that are out there, and the ones that are in production now for passenger cars, again, aren't ideal for these heavy-duty trucks and the medium-duty applications. And so we're working on different architectures that can give us some of the similar benefits of hybridization that we see in passenger cars, but can pass that on to medium and heavy-duty trucking.

LP: All right. When you say this is a difficult challenge, it's been put in a box that, something like this, it's hard to accomplish. I think that's where SwRI shines. I think that brings us to our next question nicely, but how does our work on this project fulfill the SwRI mission of research and development to benefit humankind?

RW: Well, yeah, like I said, our ultimate goal is really the decarbonization of transportation. And that has a lot of different meanings to different people. But ultimately, what it means is that we're removing CO2 emissions from transportation. And of course, that has benefits to humankind, in general. And so that has been the core of our focus within the automotive engineering division to both reduce harmful emissions and reduce carbon emissions.

And so I think all of those come together nicely in projects like this, where we're showing a significant improvement in fuel economy and engine efficiency. And it dovetails nicely with a lot of the other work that we've done in reducing emissions and demonstrating ultra-low emissions from heavy-duty and medium-duty trucks as well.

LP: All right. The Low Mass, High Efficiency Engine for Medium-duty Truck Applications is a great advancement in engine technology. Congratulations to all contributing organizations, General Motors and SwRI and the entire team on your big R&D 100 recognition.

RW: Thanks, Lisa.

And thank you to our listeners for learning along with us today. You can hear all of our Technology Today episodes, and see photos, and complete transcripts at podcast.swri.org. Remember to share our podcast and subscribe on your favorite podcast platform.

Want to see what else we're up to? Connect with Southwest Research Institute on Facebook, Instagram, X, LinkedIn, and YouTube. Check out the Technology Today Magazine at technologytoday.swri.org. And now is a great time to become an SwRI problem solver. Visit our career page at SwRI.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening.

[MUSIC PLAYING]

Southwest Research Institute has earned 54 R&D 100 awards since 1971. Each year R&D World Magazine recognizes developments regarded as among the 100 most significant technical accomplishments.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.