Click below to jump to an article of interest.

SwRI's Warner Robins Building Opens

SwRI has built its first facility outside of its San Antonio headquarters in Warner Robins, Georgia, located 3 miles from Robins Air Force Base. The 33,000-square-foot, \$18.5 million building is designed to advance national defense technology and bolster SwRI’s longstanding support for the U.S. Air Force.

SwRI employees based in Warner Robins develop advanced aerospace technology and electronic warfare (EW) solutions to detect, intercept and thwart enemy radar signals. The facility offers space for technological evaluations previously conducted off-site.

“We are proud to expand our presence in the dynamic city of Warner Robins to serve the U.S. Air Force and our nation’s warfighters,” said Winfield Greene, director of SwRI’s Advanced Electronic Warfare Department, who oversaw construction and the department’s relocation. “Warner Robins and the entire middle Georgia area are looking toward the future with the Air Force base driving progress. We are eager to broaden our impact on this community with this modern, high-tech facility.”

SwRI established a Warner Robins office in 1990, occupying leased space for decades. However, daily operations, a growing staff and increased workload created the demand for a larger building to support defense research and development. A groundbreaking ceremony was held at the site in May 2024, marking a new era in SwRI’s 78-year history.

“As SwRI’s first property outside of San Antonio, it represents an investment to support our longtime clients at Robins Air Force Base, recognizing the growing importance of its mission in national defense,” said SwRI Executive Vice President and COO Walt Downing, P.E., who was instrumental in establishing the original Warner Robins location. “We are committed to developing the most advanced technology for national defense applications. Our new facility adds resources to fulfill this mission for the base and beyond.”

For more information, visit Defense and Security.

Sustaining Aging Air Fleets

A new $250 million IDIQ contract will continue aircraft life extension programs, which include fatigue testing in SwRI’s structural testing laboratory.

SwRI is continuing its decades-long program to extend the life of aging military aircraft through a new U.S. Air Force contract worth up to \$250 million. This Indefinite Delivery Indefinite Quantity (IDIQ) contract award supports the U.S. Air Force Academy Center for Aircraft Structural Life Extension (CAStLE), created to address aging structures and materials. IDIQs are contract vehicles that fund work over specified periods of time, in this case up to eight years.

Through the contract, SwRI will evaluate and help sustain the A-10 Thunderbolt II attack aircraft, the T-38 Talon supersonic trainer, the C-5 cargo carrier and the B-52 Stratofortress bomber, among others, introduced in the 1960s and ‘70s. SwRI will also provide technical engineering support for small fleets managed by Hill Air Force Base, including the T-41 and the T-52, both trainer aircraft, and the E-9 surveillance aircraft.

“While Air Force aircraft are the primary focus, the contract allows the Navy, Army and Coast Guard to utilize the program as well,” said David Wieland, who oversees SwRI’s Aerospace Structures Section. “Due to the effectiveness of SwRI’s program, the scope of work under the current contract has grown to cover more aircraft fleets.”

To better understand how cracks originate and grow in materials, SwRI assesses the structural integrity of aircraft, using component and full-scale testing, usage monitoring, and stress and damage tolerance analyses. Additionally, SwRI will conduct teardown inspections and material failure analyses to assess risk and help ensure the airworthiness of the aircraft.

The contract will also allow SwRI to continue to support the Air Force’s ongoing digital transformation.

For more information, visit Aircraft Structural Integrity Program (ASIP).

Advancing Fuel Cell Testing

SwRI has developed new methods for evaluating the performance and efficiency of fuel cell technology in hydrogen-powered vehicles without the need for test tracks or dynamometers.

SwRI created a novel controller system for hydrogen-powered vehicles that grants full authority over their fuel cell engines. Now, engineers can extract fuel cell stacks from a vehicle and rigorously test their reactions to both normal and extreme driving conditions without physically running the vehicle. These tests are driving the creation of algorithms to help ensure the performance and efficiency of these vehicles.

In hydrogen-powered vehicles, fuel cells stacked together convert hydrogen gas into electricity through a chemical reaction. Water and heat are the only byproducts. This makes these vehicles attractive for reducing carbon emissions while ensuring long range and short refueling times. SwRI’s controller system precisely manages the full range of the system’s operations, such as its fuel flow rates, air flow rates and temperatures. Simulating different operations directly on the engine eliminates the need for conventional road testing.

The internally funded project initially analyzed a hydrogen fuel cell-powered consumer vehicle to understand the internal mechanisms that run its system. The team then extracted the fuel stack from the vehicle and installed it in a controlled environment to assess performance.

“Using our controller to manipulate functions, we can run the stacks under more extreme conditions than what the vehicle’s safety controls normally allow. This gives us a sense of how it might perform under stressors we couldn’t otherwise evaluate,” said Matthew Kubesh, one of the project’s lead investigators in SwRI’s Low Carbon Technologies Section. “Using this knowledge, we can scale up the results and apply them to help evaluate and improve the fuel cell stacks used for heavy-duty applications.”

The SwRI team is now focusing on developing predictive control models to improve fuel cell humidity management to enhance fuel cell performance.

“Too much humidity can lead to flooding and performance deterioration. Too little moisture creates high internal resistance in the fuel cell stack, which can lead to inefficiencies, degradation and potential catastrophic events,” said Venkata Chundru, a senior research engineer in SwRI’s Advanced Algorithms Section. “Our focus is replicating and extending the stack’s existing performance by dynamically adjusting the fuel-to-air ratio to achieve better humidity management.”

As the project continues, SwRI is exploring new control models and potential collaboration with commercial clients to test more complex, multi-stack setups designed for heavy-duty vehicles.

“The future of fuel cells largely lies in heavy-duty applications,” said Chundru. “To make them commercially viable, we need controllers that can manage the system efficiently and reliably under extreme operational conditions. This project is helping us get there.”

For more information, visit Fuel Cell Testing & Research.

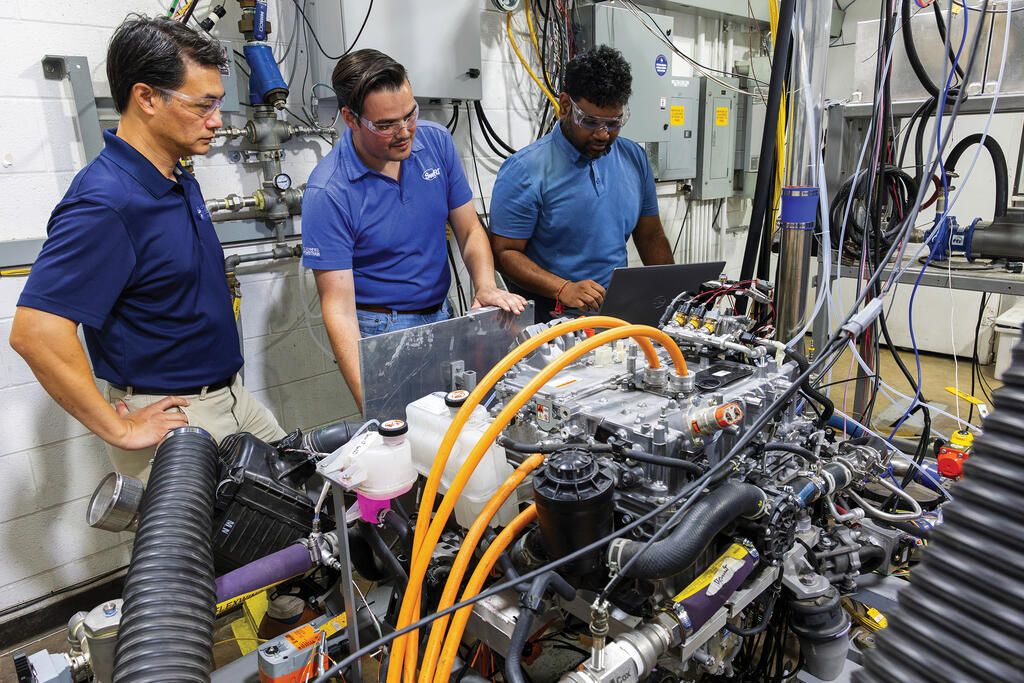

SwRI’s Richard Fu, Matthew Kubesh and Venkata Chundru extracted a fuel cell system from a vehicle to create this novel bench test setup to eliminate the need for road or dynamometer testing. Unique control technology directly manipulates fuel cell operations, allowing for advanced and robust testing and analysis.

370-Million-Mile Hail Mary Saves JunoCam

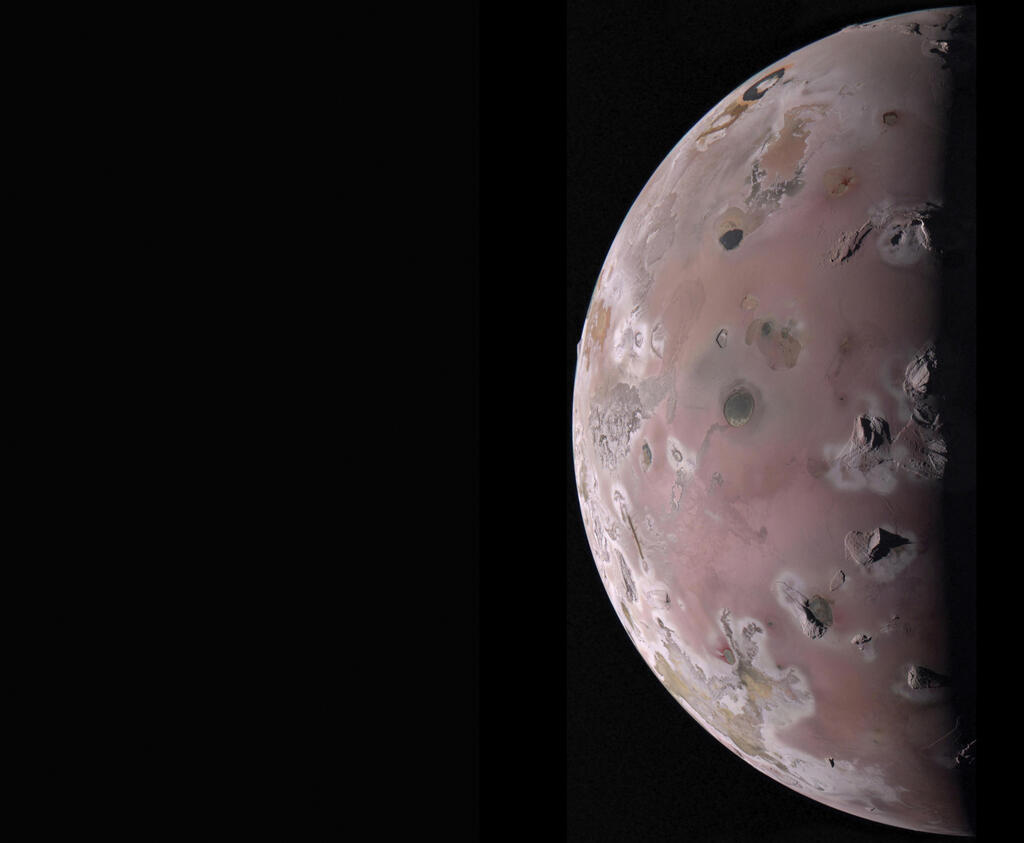

IMAGE COURTESY NASA/JPL-CALTECH/SwRI/MSSS

Following a Hail Mary attempt to repair the Juno mission’s imager, JunoCam captured this clear closeup of the north polar region of Jupiter’s volcanic moon Io. The repair team recently shared how annealing repaired radiation damage to the camera just in time to capture this image on Dec. 30, 2023.

The SwRI-led mission team of NASA’s Jupiter-orbiting Juno spacecraft executed a deepspace save in December 2023 to repair its JunoCam imager just in time to capture photos of the Jovian moon Io.

JunoCam is a color, visible-light camera. Initially included in the payload to engage the public as a citizen science program, its images have led the way to several important scientific discoveries as well. The optical unit for the camera is located outside a titanium-walled radiation vault, which protects sensitive electronic components for many of Juno’s engineering and science instruments.

This location was risky, because Juno’s journey carries it through the most intense planetary radiation fields in the solar system. While mission designers were confident JunoCam could operate through the first eight orbits of Jupiter, no one knew how long the instrument would last after that.

Throughout Juno’s prime mission of 34 orbits, JunoCam operated nearly flawlessly, returning images that the team routinely incorporated into Juno’s science papers. Then, during its 47th orbit, the imager began showing hints of radiation damage.

The team thought the issue could be tied to radiation, but pinpointing what, specifically, was damaged within JunoCam was difficult from hundreds of millions of miles away. Clues pointed to a damaged voltage regulator for JunoCam’s power supply. With few options for recovery, the team turned to a process called annealing, where a material is heated for a specified period before slowly cooling. Although the process is not well understood, heating has been observed to reduce defects in some materials.

Soon after the initial annealing process started, JunoCam began cranking out crisp images for the next several orbits. But as Juno flew deeper and deeper into the heart of Jupiter’s radiation fields, its imagery began showing problems again. By orbit 56, nearly all images were corrupted.

“After orbit 55, our images were full of streaks and noise,” said JunoCam instrument lead Michael Ravine of Malin Space Science Systems. “With the close encounter of Io bearing down on us in a few weeks, it was Hail Mary time: The only thing left we hadn’t tried was to crank JunoCam’s heater all the way up and see if more extreme annealing would save us.”

Test images sent back to Earth during the annealing showed little improvement the first week. Then, with the close approach of Io only days away, images began to improve dramatically. By the time Juno came within 930 miles (1,500 kilometers) of the volcanic moon’s surface on Dec. 30, 2023, the images were almost as good as the day the camera launched, capturing detailed views of Io’s north polar region that revealed mountain blocks covered in sulfur dioxide frosts rising sharply from the plains and previously uncharted volcanos with extensive flow fields of lava.

“Juno is teaching us how to create and maintain spacecraft tolerant to radiation, providing key insights that will benefit not only Juno, but also satellites in orbit around Earth,” said SwRI’s Dr. Scott Bolton, Juno’s principal investigator. “I expect the lessons learned from Juno will be applicable to both defense and commercial satellites as well as other NASA missions, such as the Europa Clipper mission currently en route to the Jovian system.”

The team recently reported the results from the long-distance save at the Institute of Electrical and Electronics Engineers Nuclear & Space Radiation Effects Conference.

For more information, visit https://www.missionjuno.swri.edu/ or https://www.nasa.gov/juno.

Spherical Near-Field Antenna Evaluation

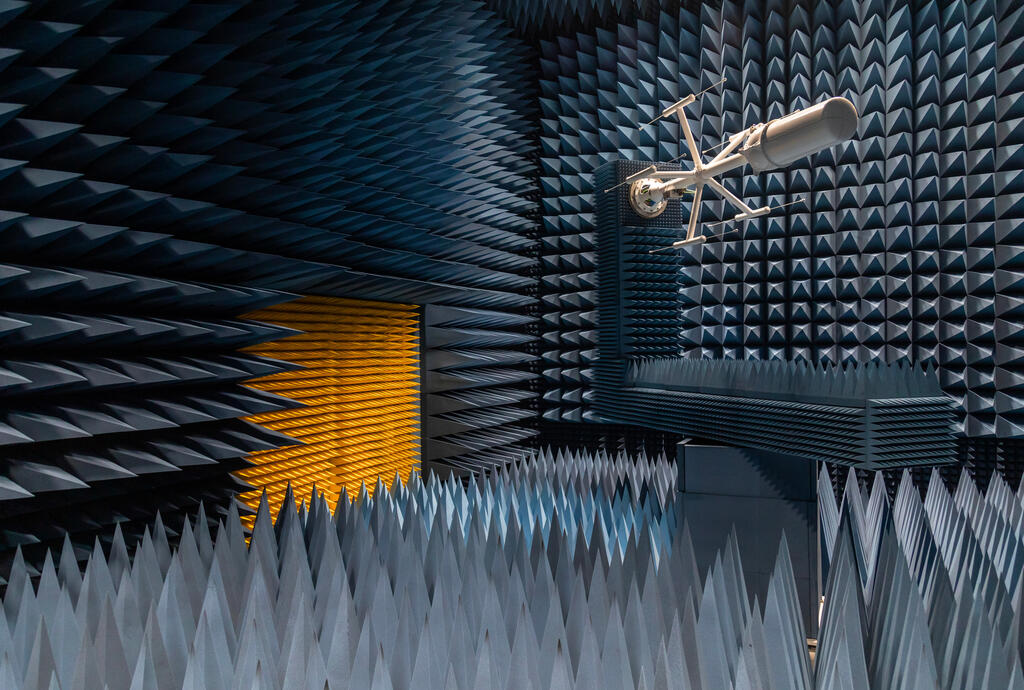

SwRI is expanding its antenna measurement capabilities with a state-of-the-art spherical near-field antenna range. The 1,260-square-foot indoor range, lined with radio frequency and microwave foam absorbers, is equipped to accurately sample the near field of an antenna, which can be mathematically transformed into far-field data.

SwRI’s 1,260-square-foot indoor spherical near-field antenna range evaluates the R&D 100 Award-winning AS-750 Wideband Conformal Continuous-Slot Antenna Array. The antenna testing chamber, lined with radio frequency and microwave foam absorbers, is equipped to accurately sample the near field of an antenna, which can be mathematically transformed into far-field data. Analyzing both fields allows a more complete performance evaluation of an antenna under test.

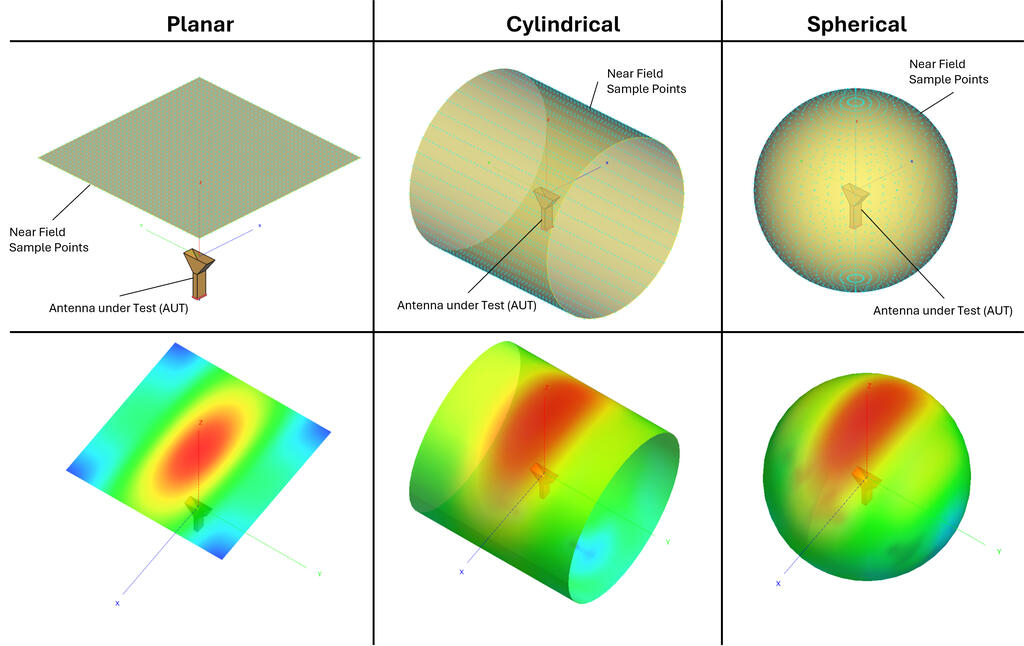

SwRI’s new indoor antenna range supports 3D spherical data collection (right), the most comprehensive and flexible method of measuring antenna patterns for all antenna types. Other techniques, such as planar (left) or cylindrical (center) collection methods, offer more limited perspectives.

“Near field” refers to the complex electromagnetic fields close to an antenna, while “far field” encompasses the predictable planar waves farther away. Analyzing both fields allows a more complete performance evaluation of an antenna under test. Near-field measurements are typically collected in a planar, cylindrical or spherical formation.

“Spherical data collection is the most comprehensive and flexible method of measuring radiation patterns for all antenna types,” said Dr. Jimmy Li, a lead engineer in SwRI’s Defense and Intelligence Solutions Division. “We get the full 3D radiation pattern data for an antenna — not just limited perspectives obtained with other methods.”

Antennas enable the transmission and reception of signals and are the interface between electromagnetic waves and electronic devices. Testing is necessary to evaluate performance and ensure compliance with industry standards and regulations. Antennas are crucial for a wide range of technologies, including cellular networks, Wi-Fi, radar, satellite communications and positioning and navigation systems.

SwRI’s spherical near-field antenna range includes several new advantages:

- No restrictions associated with antenna far-field distances exceeding the size of the range

- A built-in, overhead, half-ton hoist to install large antennas up to 10 feet in diameter and 1,000 pounds

- Operation at frequencies from 200 megahertz to 40 gigahertz

- Faster data collection enabled by continuous rotation sampling

- Full characterization of antenna-radiated patterns, including multipolarization 3D patterns across all angles

- Faulty antenna element diagnostics, array performance evaluations, radome systems tuning and reflector surface area mapping

- No limitations due to weather fluctuations that impact outdoor ranges

- No limitations from Federal Communications Commission (FCC) regulations that impact outdoor ranges

“Because the range is indoors, we do not have to follow FCC requirements regarding antenna height and other transmission restrictions for outdoor antenna testing,” said Nils Smith, vice president of SwRI’s Defense and Intelligence Solutions Division. “We can now perform thorough testing of antennas on-site at SwRI with more versatility for our clients.”

The facility will support emerging millimeter wave technologies in the next phase of development, a crucial component for ultra-fast 5G data transmission.

SwRI designs, develops and tests antennas and signal processing software for government and industry clients, including the Navy, Air Force, Marines and intelligence entities.

For more information, visit antennasolutions.swri.org.

PUNCH Completes Commissioning

All four spacecraft of the SwRI-led PUNCH (Polarimeter to Unify the Corona and Heliosphere) mission have successfully maneuvered into their final science orbits as of August 7.

IMAGE COURTESY NASA’S CONCEPTUAL IMAGE LAB

This visualization shows the four PUNCH spacecraft in their science orbits. Spread around Earth along the day-night line, the four spacecraft provide a continuous, unobstructed view of the Sun and its surroundings.

The NASA spacecraft launched into Earth orbit on March 11 and are now spread out along the planet’s day-night boundary, giving the mission a continuous, unobstructed view of the Sun and its surroundings. This allows the mission to study how the Sun’s outer atmosphere, or corona, turns into a constant outflow of material that travels across the solar system, called the solar wind. PUNCH’s four suitcase-sized spacecraft act as a single virtual instrument 8,000 miles across. They image the solar corona as it transitions into the solar wind that fills and defines our solar system.

“We want to measure the solar wind globally around the star in near real time,” said PUNCH’s principal investigator, Dr. Craig DeForest, from SwRI’s Space Science and Exploration Division in Boulder, Colorado. “The planet gets in the way from the point of view of any one spacecraft, so we had to spread them around the planet to look everywhere all at once.”

IMAGE COURTESY NASA’S CONCEPTUAL IMAGE LAB

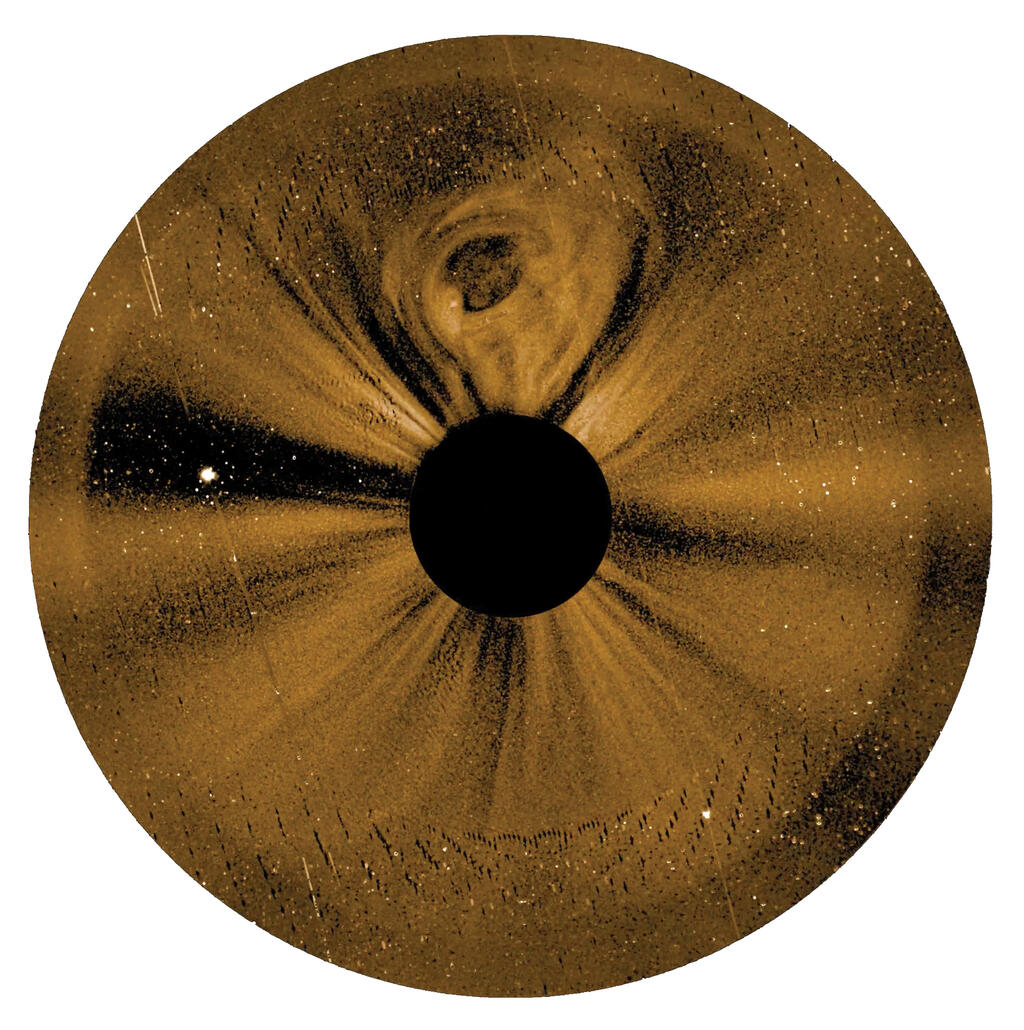

NASA’s PUNCH mission, led by SwRI, uses its Narrow Field Imager to collect images of solar activity. By blocking the Sun’s bright face, NFI captures the Sun’s atmosphere in unprecedented detail. The June 3 CME shown at the top of the image grew to enormous size, 100 times that of the Sun, as it traveled across the solar system.

During a media event at the 246th American Astronomical Society meeting in Anchorage, Alaska, DeForest discussed early accomplishments. Even before the spacecraft constellation had completed commissioning, early PUNCH data showed coronal mass ejections, or CMEs, erupting from the Sun and traveling across the inner solar system.

“These preliminary movies show that PUNCH can actually track space weather across the solar system and view the corona and solar wind as a single system,” said DeForest. “This big-picture view is essential to helping scientists better understand and predict space weather driven by CMEs, which can disrupt communications, endanger satellites and create auroras at Earth.”

One satellite carries the Narrow Field Imager (NFI), while the other three each carry a Wide Field Imager (WFI). The U.S. Naval Research Laboratory developed the NFI coronagraph, which blocks out the bright light from the Sun to better reveal details in the Sun’s corona. The SwRI-developed WFIs capture images of the outermost portion of the solar corona and the solar wind in the inner solar system. The mission then combines these individual views into a wide-field mosaic that allows PUNCH to track space weather events from the Sun all the way to Earth.

PUNCH’s early combined views are now available publicly as “Level 2” science data. To bring out details in the faint corona and solar wind, the PUNCH images require multiple steps or “levels” of processing, from 0 (least processed) to 3 (fully processed). The level 2 data stitch together images from the different spacecraft into a mosaic, as if they were taken by a single science instrument at the same time.

The processed PUNCH images are available for download from NASA’s Solar Data Analysis Center, and more information about the data is available at SwRI’s data access page.

For more information, visit Heliophysics.

Targeting Malaria Source

SwRI used its drug formulation and manufacturing expertise to fabricate two bed netting prototypes that target malaria-causing blood parasites. In collaboration with researchers at the Harvard T.H. Chan School of Public Health and Oregon Health & Science University (OHSU)/Portland Veterans Affairs Medical Center (PVAMC), SwRI chemists designed netting systems to deliver antimalarial drugs called endochin-like quinolones (ELQs), destroying Plasmodium parasites transmitted by mosquitoes.

“If an infected mosquito hits or lands on either type of netting, it’s essentially disinfected,” said Institute Scientist Dr. Mike Rubal, who contributed to an article in Nature about this research. “The best defense against malaria has been insecticide-treated bed nets or those coated with larvicides, but mosquitoes are developing resistance to those prevention methods. This novel approach targets the source of the disease.”

In 2023, the World Health Organization reported 263 million cases of malaria and nearly 600,000 deaths worldwide. The disease remains pervasive even with preventive measures and available treatments. Resistance to larvicides and pesticides is a growing concern.

Rubal’s team coated a commercially available polyester bed net with an ELQ solution synthesized at OHSU/PVAMC. SwRI also developed a second solution, blending ELQ into a hot-melt extrusion of high-density polyethylene filaments that can be woven into yarn for netting. The team at Harvard evaluated both netting systems for efficacy.

“We desperately need innovation in malaria control. This study offers a new, effective way to stop the transmission of malaria parasites, which we hope will reduce the burden of this devastating disease in Africa and beyond,” said co-author Dr. Flaminia Catteruccia, Irene Heinz Given Professor of Immunology and Infectious Diseases at Harvard and a Howard Hughes Medical Institute investigator.

For more information, visit Pharmaceutical Development.

Improving Oil Recovery, Carbon Sequestration

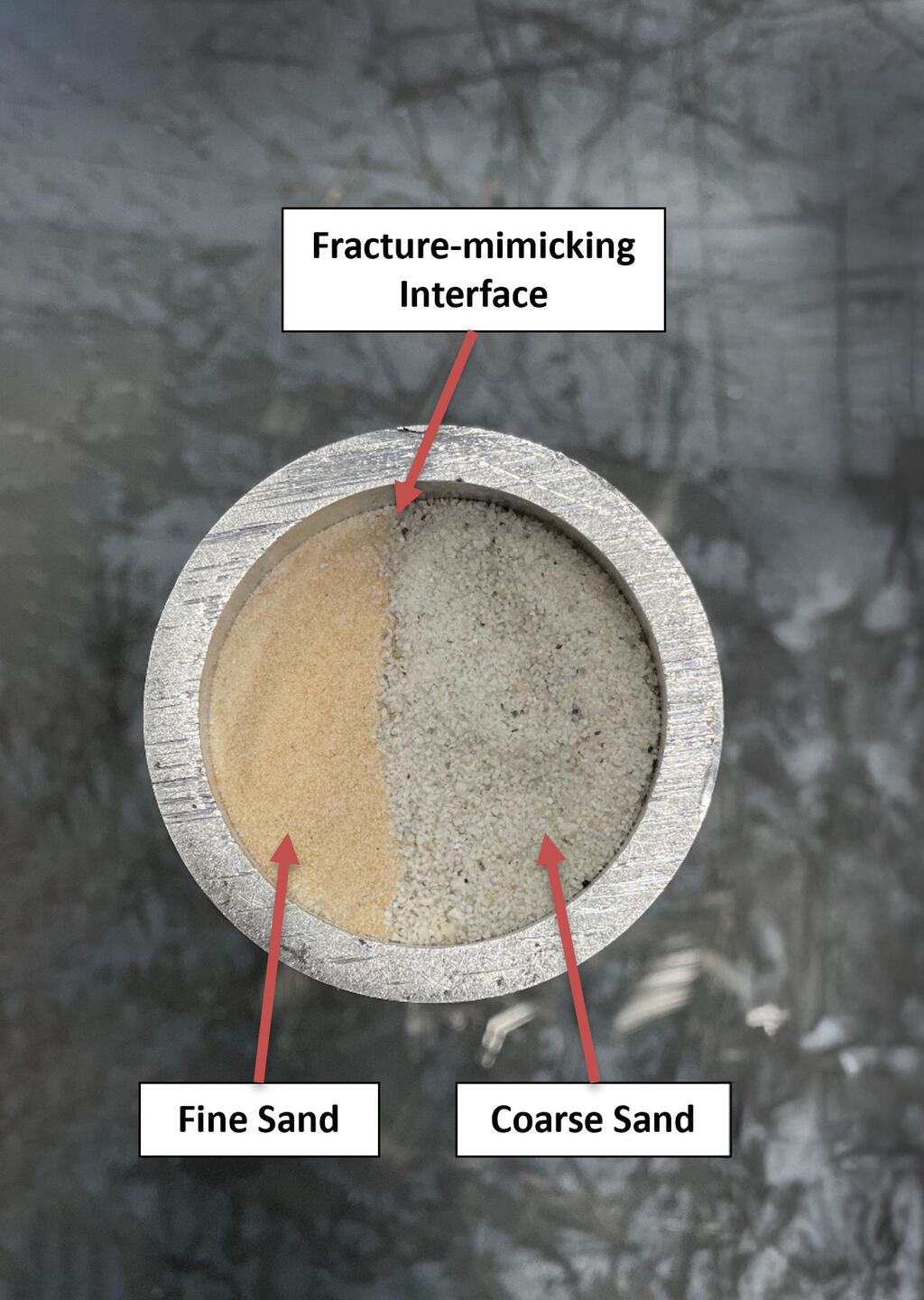

To evaluate the effectiveness of using sCO2 foams for oil recovery and sequestration, SwRI tested them using a heterogeneous sand-pack that mimics the underground formations that foams would encounter in oil fields.

SwRI and The University of Texas at Austin (UT Austin) have evaluated a promising approach to improve long-term carbon storage in depleted oil and gas reservoirs. The team proposes using foam-entrapped supercritical carbon dioxide (sCO2) to prevent stored and captured carbon from moving back to the surface. The project is supported by the Energize program, a joint effort between SwRI and UT Austin to enhance scientific collaboration.

Carbon capture, utilization and sequestration (CCUS) involves using captured CO2 to extend its usefulness before it’s stored underground.

“Injecting CO2 into wells to enhance oil recovery allows it to perform work underground while being captured and stored,” said SwRI’s Angel Wileman, a co-principal investigator of the project. “Unlike fresh water or oil — which we’d rather not use — CO2 is a substance we already aim to keep underground.”

To ensure that stored CO2 remains stable underground and doesn’t migrate to the surface, SwRI applied principles from traditional CO2-enhanced oil recovery methods to investigate the stability and behavior of foam-entrapped CO2 at high-temperature and high-pressure reservoir conditions. Under these conditions, the CO2 reaches its supercritical state, exhibiting gas-like viscosity and liquid-like density, which influences its mobility and storage behavior.

Supercritical CO2 foams exhibit a behavior known as shear thinning, meaning their viscosity decreases under higher shear rates. This allows them to flow more easily through low-permeability zones while limiting flow into high-permeability regions. As a result, they improve sweep efficiency for oil recovery and help reduce the risk of CO2 migration by limiting channeling and preferential flow through fractures.

The project expanded SwRI’s small foam generator facility, making it possible to evaluate unconventional technology at a much wider scale.

For more information, visit Fluids Engineering.

Detecting Debris On-Orbit

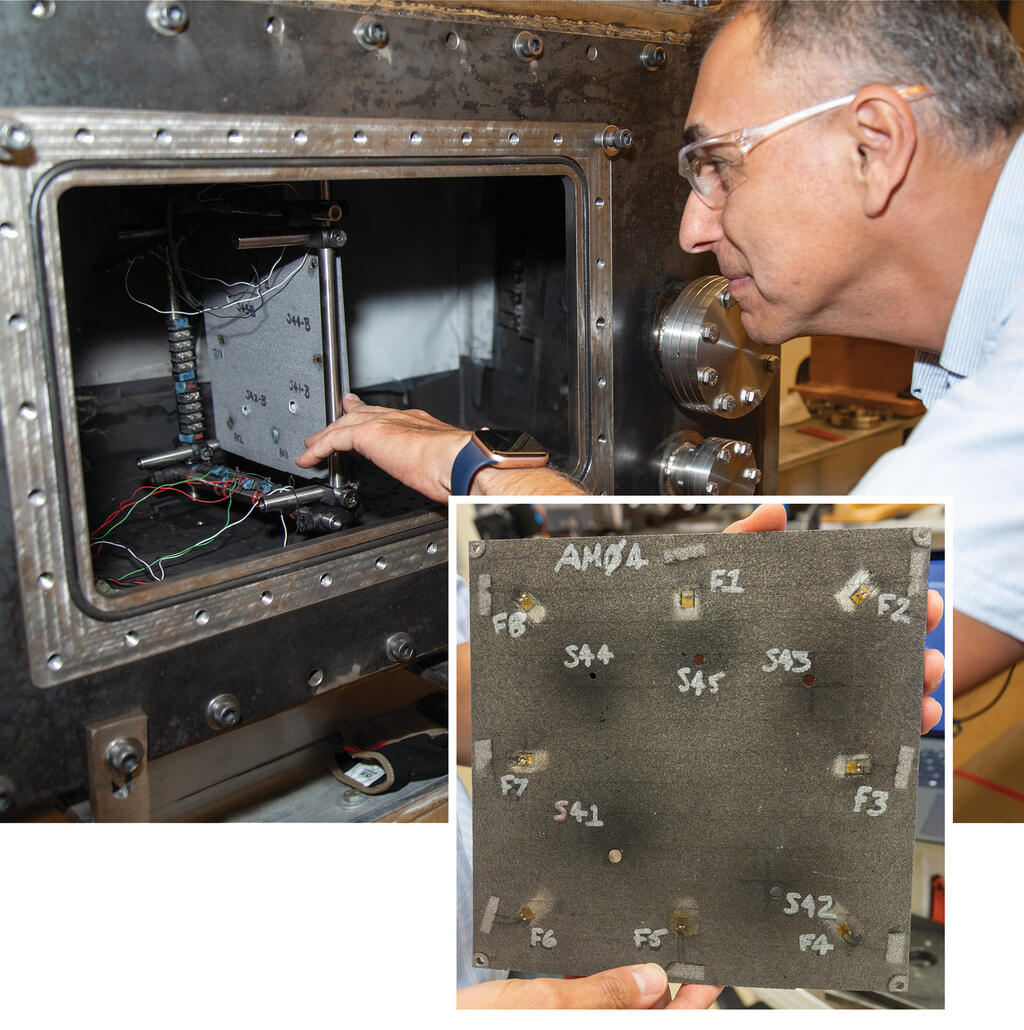

SwRI has developed and tested a micrometeoroid and orbital debris (MMOD) detection and characterization system designed for satellites and spacecraft to monitor impacts from space debris. The system provides critical post-impact data, ensuring awareness of an impact even when damage is not immediately apparent.

Space debris around Earth is a growing problem, a result of commercial satellites exploding, anti-satellite missile tests and accidents that contribute to a growing junk field. Depending on its location, debris can remain in orbit for years, posing a threat to operational spacecraft.

The MMOD system can be mounted onto a spacecraft or integrated into its design. It consists of a structural element embedded with sensors that collect data for software analysis to identify impact details. These data can provide insights into the size and volume of particles orbiting Earth, including many that are too small to be seen from the planet’s surface. It can also alert operators if their spacecraft or satellite has been hit.

“Most spacecraft survive minor impacts without systems breaking or operators on Earth knowing,” said SwRI Institute Scientist Dr. Sidney Chocron, who led development of the MMOD detection and characterization system. “Our device is designed to send data back to Earth with important insights before any damage is apparent.”

These data could help NASA and the industry develop more resilient future spacecraft. While it doesn’t help existing spacecraft directly avoid collisions, it could play a role in early warning systems. If a satellite detects a debris strike, it could warn others in the same orbit to move out of the way, if possible.

“Ultimately, our primary goal is to map and characterize the MMOD debris field around the Earth to better protect future missions,” Chocron said. “Our MMOD detection and characterization system is a step toward better understanding and mitigating those risks.”

For more information, visit Ballistics & Explosives.

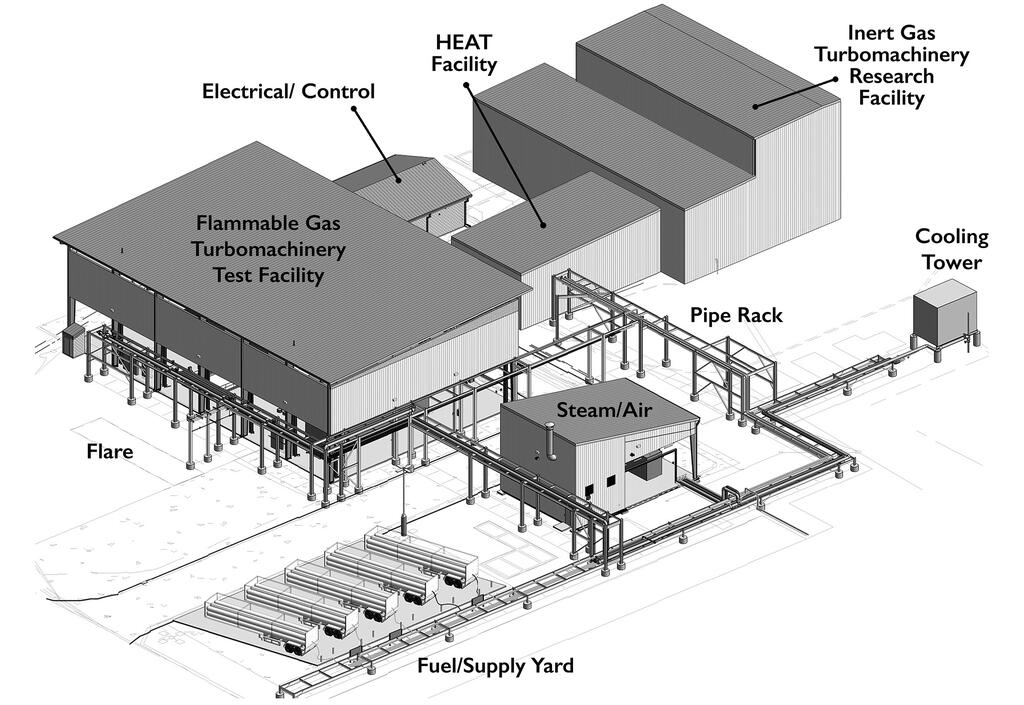

Expanding Flammable Gas Machinery Testing

SwRI is significantly expanding its testing and research capabilities with a new hydrocarbon research facility. It will provide megawatt-scale testing of machinery and energy systems powered by hydrocarbons and other flammable gases. The 90,000-square-foot facility will evaluate a wide range of equipment for efficiency, safety and durability.

The facility is designed to safely use flammable gases including hydrogen, hydrocarbons, organic fluids and refrigerants. Hydrocarbons like natural gas are organic compounds composed of hydrogen and carbon atoms and serve as a fundamental building block for many fuels, including petrochemicals. Some heat pumps utilize advanced refrigerants including hydrofluorocarbons or ammonia. SwRI’s new hydrocarbon research facility will enable testing of machinery such as gas turbines, turbo compressors, reciprocating compressors, industrial heat pumps and many other systems that use these fluids in power generation or conversion applications.

"Natural gas fuels over a third of the U.S. power supply and can be produced, stored and transported affordably relative to other sources of energy,” said Dr. Tim Allison, director of SwRI’s Machinery Department. “It offers significantly reduced carbon emissions in comparison to other fossil fuels. Our new testing capabilities will facilitate technology development to improve the efficiency, emissions, reliability, affordability and safety of natural gas machinery and systems.”

The new complex will operate out of three buildings, including an open-sided facility for testing large machinery. The electrical and control building provides up to 5 megawatts of electric power to support testing activities and includes fiber-optic connections for fast data transfer across the facility. The third building will house a steam generator to facilitate advanced testing scenarios requiring compressed air or steam. Additionally, the facility will have a fuel yard to safely store and handle various flammable gases. Construction will be completed in 2025.

For more information, visit Machinery.

Solar Events Impact Velocity of Pickup Ions

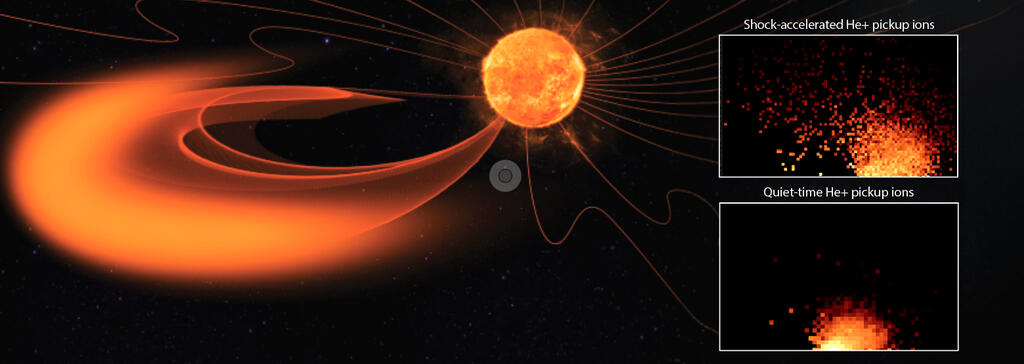

SwRI scientists have discovered how solar activity affects the velocity distribution and evolution of helium pickup ions. These charged particles are created when neutral particles originating outside of our solar system are ionized by solar ultraviolet radiation and captured by the interplanetary magnetic field.

A new study led by SwRI’s Dr. Keiichi Ogasawara indicates that these pickup ions are a wellspring of solar energetic particles (SEPs). These high-energy accelerated particles include protons, electrons and heavy ions produced by solar events like flares and coronal mass ejections (CMEs). Using data from NASA’s Solar Terrestrial Relations Observatory, SwRI detected the initial characteristics of helium pickup ion acceleration through several CME events.

“We carefully identified the specific properties of the ions and used them to trace the physical energy transfer processes,” Ogasawara said. “We also considered the roles played by different types of interplanetary shocks, such as when fast-moving solar wind disturbances collide with slower-moving solar wind plasmas.”

Understanding how and when SEPs occur is critical because, at higher energies, they can penetrate spacecraft and spacesuits, posing a radiation hazard to astronauts. SwRI also studied the velocities of individual helium pickup ions in relation to their local magnetic field orientations and identified characteristic behaviors associated with various shocks associated with CMEs.

“The velocity distribution of pickup ions is quite different from that of the solar wind,” Ogasawara said. “In fact, they can be twice as fast as the solar wind even during relatively quiet times. Because of this difference, pickup ions are more effectively accelerated to even higher energies than normal solar wind particles.”

In comparison to SEPs, the solar wind is a continuous lower-energy flow of plasma emitted by the corona, the Sun’s outer atmosphere.

For more information, visit Heliophysics.

IMAGE COURTESY NASA SCIENTIFIC VISUALIZATION STUDIO/ ANIL RAO/UNIV. OF COLORADO/MAVEN/NASA GSFC

New SwRI research indicates that helium pickup ions are a wellspring of solar energetic particles, high-energy charged particles traveling at high speeds. When boosted by solar shocks such as coronal mass ejections, they can penetrate spacecraft and spacesuits, posing a radiation hazard to astronauts.

Megawatt-Scale Heat Exchanger Evaluations

SwRI is expanding its heat exchanger testing capabilities to include megawatt-scale performance evaluations, a capability matched by only a handful of facilities worldwide. Heat exchangers efficiently transfer heat between two or more fluids without mixing for a wide variety of heating and cooling applications. These efforts are being led by Dr. Ashok Thyagaragan and Dr. Eugene Hoffman.

“SwRI’s expanded heat exchanger testing capabilities will address a significant market gap for high-heat transfer rates involving high-temperature and -flowrate applications,” said Research Engineer Dr. Eugene Hoffman of SwRI’s Fluids Engineering Department. “This was the perfect time to advance our capabilities and expertise to meet increasing demands for specialized and custom heat exchanger testing capabilities that few facilities can accommodate.”

The rapidly growing heat exchanger market is projected to reach more than $30 billion over the next decade. Heat exchange technology is vital in automobiles, data centers, aerospace technology and defense applications. Rather than relying on a one-size-fits-all approach, SwRI has adapted existing equipment and infrastructure to offer customized heat exchanger testing to clients. The facilities offer a wide range of unique and complex testing requirements to meet diverse and robust market demands.

“Our testing capabilities apply to many different systems needing thermal management,” Hoffman said. “From drones to heavy-duty vehicles and power systems, we provide a comprehensive equipment suite to help clients manage a variety of thermal systems while supporting their design and testing needs.”

For more information, visit Heat Exchanger Performance Testing & Research.

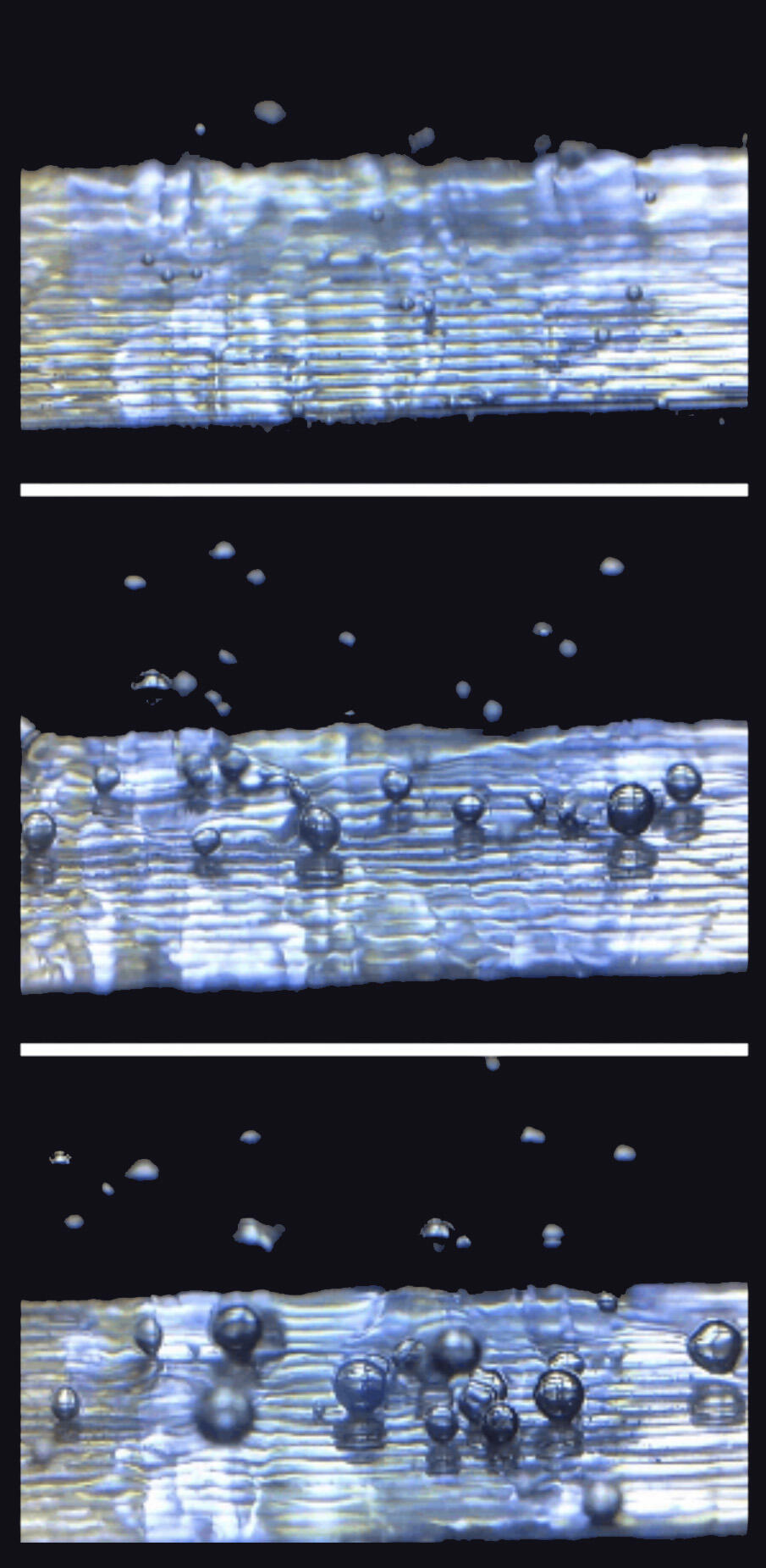

Evaluating Electrolyzer at Low Gravity

NASA’s TechLeap Prize competition selected an SwRI/UTSA team to evaluate electrolyzer technology designed to improve the production of propellants and life support compounds on other worlds. This image illustrates how gas bubbles evolve at different rates at Earth (top), Martian (middle) and lunar (bottom) gravity.

SwRI and The University of Texas at San Antonio (UTSA) have received a NASA TechLeap Prize to flight test novel electrolyzer technology designed to improve the production of propellants and life-support compounds on the Moon, Mars or near-Earth asteroids. The project, known as the Mars Atmospheric Reactor for Synthesis of Consumables (MARS-C), is led by SwRI’s Kevin Supak and Dr. Eugene Hoffman and UTSA’s Dr. Shrihari Sankarasubramanian.

SwRI and UTSA will evaluate the performance of a patent-pending electrolyzer developed with NASA support by Sankarasubramanian, assistant professor in UTSA’s Department of Biomedical and Chemical Engineering, and his team. The device applies a voltage across two electrodes to drive the electrochemical conversion of a simulated Martian brine and carbon dioxide into methane and other hydrocarbons. This technology is designed to use local resources on the Moon or Mars to produce fuel, oxygen and other life support compounds needed for long-term human habitation.

The work builds on previous research conducted by SwRI that involved studying boiling processes under partial gravity aboard parabolic flights, which simulate low gravity conditions. Designed to understand how liquids might behave on lunar or Martian surfaces, the research demonstrated that partial gravity affects surface bubble dynamics, which can impact gas production rates.

“In a partial gravity environment, like the Moon or Mars, a reduced buoyancy effect on gas bubbles in an electrolyzer poses challenges that aren’t present on Earth,” Supak said. “We lack an understanding about chemical processes that leverage bubble nucleation in low gravity, which is the gap we aim to fill.”

To address this, SwRI and UTSA will integrate the technology into an existing SwRI-built flight rig and test it aboard a parabolic flight, capitalizing on the Institute’s successful history of testing technology in reduced gravity aircraft and suborbital spacecraft. The flight is currently planned for 2026.

For more information, visit Fluid Physics for Space Applications.

Determining How Gas Blends Affect Storage Tanks

SwRI is addressing the challenges of a hydrogen-powered future. In collaboration with NYSEARCH, SwRI is investigating how blending hydrogen into liquid natural gas (LNG) could affect the integrity of the LNG storage tanks.

Natural gas is widely used to power appliances and heat homes. By blending hydrogen into these existing natural gas streams, utilities can reduce the carbon footprint of energy delivery while leveraging current natural gas infrastructure. In the next decade, some gas companies are planning to use hydrogen-natural gas blends to curb carbon emissions.

LNG peak sharing facilities help stabilize energy supply and pricing during periods of high demand. In these systems, natural gas is liquefied and stored in massive cryogenic tanks during times of low usage, typically in summer, and regasified during winter months when demand surges. The potential introduction of hydrogen into these systems raises important safety questions.

“A new challenge for blending hydrogen into natural gas distribution lines concerns energy storage mechanisms,” said Angel Wileman, who leads SwRI’s Thermofluids Section. “We are investigating what happens to these tanks when hydrogen-natural gas blends undergo the liquefaction process, which transforms gas into its liquid phase, and stored for months.”

The industry is concerned that natural gas-hydrogen blends may dip below the storage tank’s temperature rating, affecting its safety and pressure integrity. SwRI is conducting experiments to determine if these tanks can endure lower temperatures. To simulate hydrogen bubbling into liquid natural gas inside the tanks, engineers are building a custom test rig that introduces hydrogen into an LNG-filled tank.

For more information, visit Hydrogen Energy Research.