New technologies are advancing the energy storage capacity of batteries, cells and packs that power handheld devices, electric vehicles and grid-scale energy storage systems. The Energy Storage Technology Center® (ESTC) at Southwest Research Institute is an internationally recognized laboratory for battery research, development and testing in accordance with government and industry standards. In addition to battery safety and abuse testing, SwRI’s ESTC features technology experts from diverse scientific fields to support R&D and evaluation of energy storage systems.

Contact Scott Sjovall or call +1 210 522 5065 to inquire about testing services.

The turnkey advantage of testing batteries at SwRI

We offer turnkey testing and research services for battery cell, module and pack levels. SwRI can perform all battery mechanical, electrical, thermal and performance testing in-house at a single location. Analysis and testing include, among other services:

- Gaseous and particulate emissions measurement and characterization

- Nondestructive and destructive post-test analysis

- Teardown analysis

Testing is performed under an ISO 9001-certified quality management system, with most tests covered under an ISO 17025 testing laboratory accreditation. Disposal of any hazardous waste follows ISO 14001.

Battery Abuse Testing

The ESTC performs rigorous battery abuse testing and analyzes how batteries, cells and packs respond. This allows manufacturers and consumers to better understand how, when and why failure can occur.

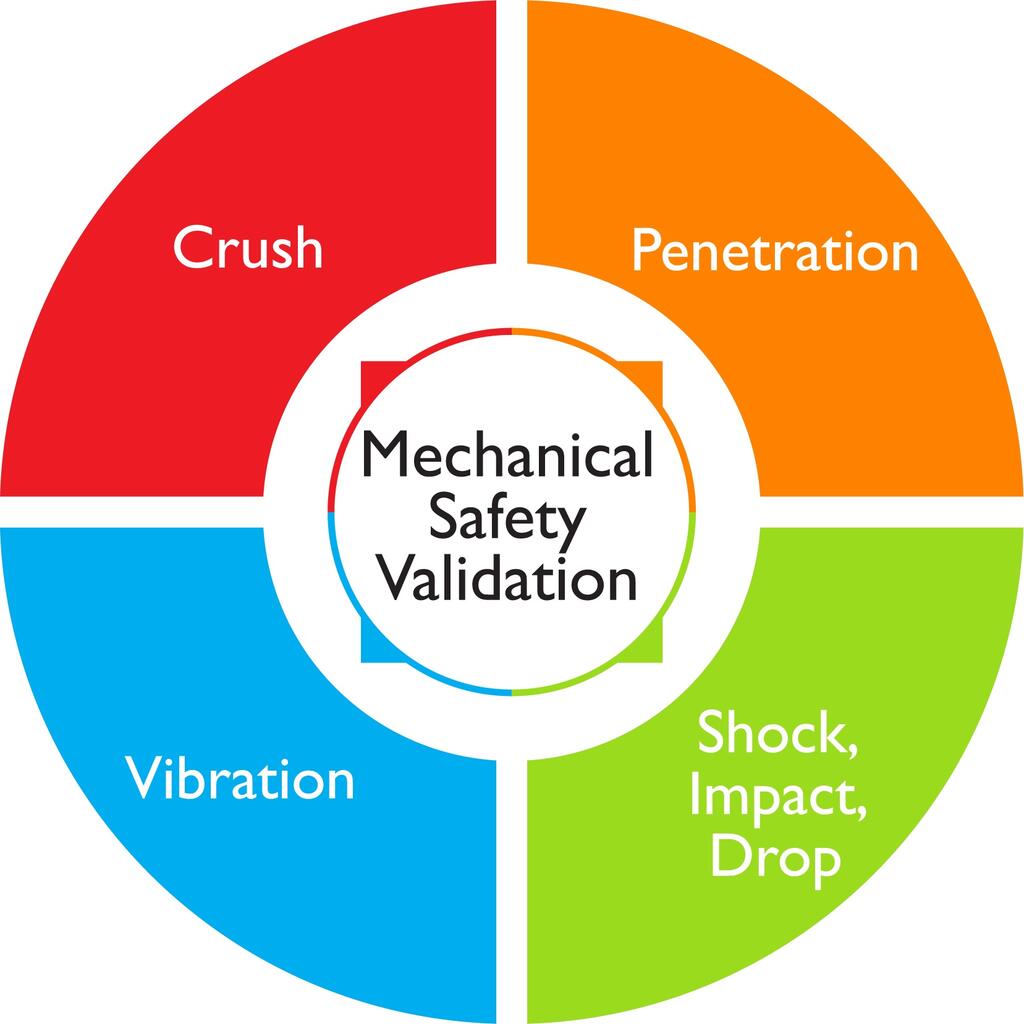

Mechanical Testing

- Crush

- Nail penetration

- Vibration

- Shock

- Drop

- Impact

- Rotation

Battery Safety Testing

We have dedicated engineering staff capable of designing custom battery safety testing plans, enclosures and stands. In addition to standardized battery safety testing, we commonly create custom testing plans and testing rigs.

Environmental Testing

- Extreme conditions: –70°C to +175°C

- Altitude simulation up to 32,000 m

- Fire resistance and flammability

- Corrosive salt fog and dust

- Thermal runaway prevention

Battery Fire Testing

We help clients characterize thermal properties of batteries through electrical safety validation and battery fire testing.

Electrical Testing

- External short circuit

- Overcharge and over-discharge

- 920 volts (652 amps)

- 1,200 volts (1,333 amps)

- 2,000 volts (600 amps)

- Imbalance

- Dielectric voltage withstand

- Isolation resistance

- Continuity

Learn more from our Automotive Webinar Series

Visit the SwRI Automotive Webinar Series to learn more about battery safety and abuse testing.

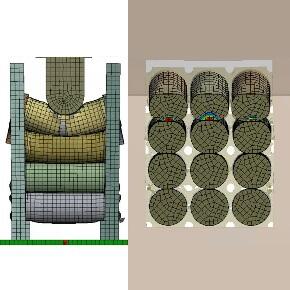

Battery Analysis for Mechanical Abuse

Learn how CAE models are helping analyze lithium-ion batteries, predicting internal short circuit, thermal runaway and fire propagation at cell, module and pack level.

Overcharge Tolerance of Aged LMO Cells

Learn how aging in lithium ion manganese oxide (LMO) battery cells can lead to swelling, overcharging, failure and other risks.

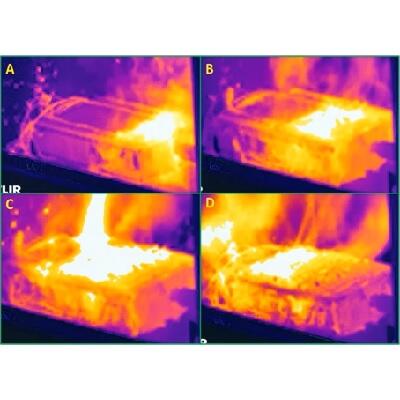

Characterizing Emissions from Battery Fires

Understanding thermal runway in lithium-ion battery fires and the influences of cell arrangement and battery chemistry in emissions.

Visit Fuel Tank & Battery Testing to learn more about battery fire testing in accordance with ECE 100 Annex 8E and GB/T 31467 3-2015, Section 7.10 and other standards.

Battery Testing Standards

SwRI can conduct testing to a variety of custom or modified battery testing standards and procedures, including, but not limited to:

- UL 9540 / UL 9540 A

- UL 2580

- UL 1973

- UL 1642

- SAE J2929

- SAE J2464

- UN ECE R100

- UN 38.3

- DO-311

- NAVSEA S9310

- ICE-62660

- MIL-PRF-32565 C (Qualified Laboratory)

Related Services

We provide R&D and analysis services across the electric powertrain.

- Battery Immersion Cooling Testing & Research

- Battery Testing & Research

- Electric Mobility Solutions

- Electric Powertrain Systems

- Energy Storage Technology Center

- Hybrid & Electric Vehicle Battery Testing Laboratory

- Hybrid & Electric Vehicle Testing

- UN 38.3 Transportation Testing for Lithium-Ion Batteries