SwRI’s Integrally Geared Supercritical CO2 Compander has been named one of the top innovations of 2022, receiving a prestigious R&D 100 Award. Pipeline & Gas Journal also recognized the compander as the “Best Management Advancement Technology” at the R&D 100 Awards Gala held on November 17. Using supercritical carbon dioxide, the revolutionary technology converts heat, like sunlight, into usable energy, while reducing carbon emissions. Our guests tell us what makes the new compander superior to conventional turbomachinery. They also explain how the groundbreaking equipment and highly-efficient sCO2 power cycles are moving us toward a cleaner energy future.

Listen now as SwRI engineers Dr. Tim Allison and Dr. Jason Wilkes discuss the transformational compander and other sCO2 solutions.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): Recognized as one of the most significant innovations of 2022, the integrally geared, supercritical CO2 compounder converts sunlight and other heat into electricity. The technology just won a prestigious R&D 100 Award. We're learning about the compounder and groundbreaking sCO2 solutions next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now, let's understand it better. You're listening to the Technology Today podcast presented by Southwest Research Institute. Transcripts and photos for this episode and all episodes are available at podcast.swri.org.

Hello and welcome to Technology Today. I'm Lisa Peña. Today, we are highlighting the integrally geared, supercritical CO2 compounder, winner of a 2022 R&D 100 Award and recognized by R&D World Magazine as a top 100 innovation of the year. We're going to explain what it is, how it works, and what makes it revolutionary. We'll also get into a larger conversation about clean, efficient, supercritical carbon dioxide and the latest sCO2 technology developments at SwRI. Our guests today are SwRI engineer Dr. Tim Allison, Director of our Machinery Department, and Dr. Jason Wilkes, Manager in our Machinery Department, who led the development of the award-winning compounder. Thanks for being here, Tim and Jason.

R&D World Magazine recognized SwRI and Hanwha Power System’s Integrally Geared Supercritical CO2 Compander as being among the 100 most significant innovations for 2022.

Dr. Jason Wilkes (JW): Thank you.

Dr. Tim Allison (TA): Thank you.

JW: Appreciate it.

TA: Yeah, our pleasure. Excited to be here.

LP: Tim, I'd like to start with you. This is your second time on the podcast. We first learned about sCO2 research and development at SwRI on Episode 22. Great to have you back, so let's recap a little of our conversation from then. For our listeners new to this topic, what is sCO2 and why is it a better energy option?

TA: Yeah. And that's a question that we get a lot, so I'm happy to recap. "sCO2" stands for "supercritical carbon dioxide," and it's just the carbon dioxide that you hear about a lot. But when we call it "supercritical," that means it's at conditions that are above its critical point. So CO2 has a critical point, which is a pressure that's above 1,070 PSI and a temperature above 88° Fahrenheit. So when you're above those conditions, it's in what's called the "supercritical phase" for CO2. Like there's a gas phase or a liquid phase, it's just a different set of conditions. That's supercritical. And we use it for power cycles as a working fluid. So all power conversion systems that are machinery-based, which is what most of the world's power is made from, use working fluids like steam in a steam turbine cycle or air in a gas turbine. So when we use supercritical CO2 in a power cycle, we're just swapping out the steam or the air with this high-pressure and higher temperature CO2.

And that has a lot of advantages that make it really interesting and compelling. I would say that there are three real big advantages. CO2 at those conditions is very dense. That's the first one. When we operate with CO2, it enables high efficiencies. And then the last one is that some implementations of supercritical CO2 cycles can allow for very easy carbon capture when we use fossil fuel for power. So if I unpack the three, the really high density is important. If you look at the history of power generation in the world, there's been a migration towards lower cost and more power-dense systems. And CO2 is really the next step of that. The machinery that you make that operate with supercritical CO2 can be about a tenth of the size of modern steam turbines, so it's really a transformational step in increasing the compactness and modularity of those systems.

I mentioned CO2 being more efficient than steam, especially at high temperatures, and that's just driven by some of the gas properties of CO2. And carbon capture is pretty exciting as well. It allows us to use natural gas, which is still very available and one of our lowest cost fuel sources for energy, but to do it in a way that is consistent with decarbonization goals. So if you do combustion in a supercritical CO2 environment, you make water, you make more CO2. But if you make it up in supercritical conditions, it's already there and ready for pipeline transport. It's had a lot of the conditioning that's needed to capture CO2 from existing power plant technologies. So those are several of the reasons that CO2 is a really compelling technology.

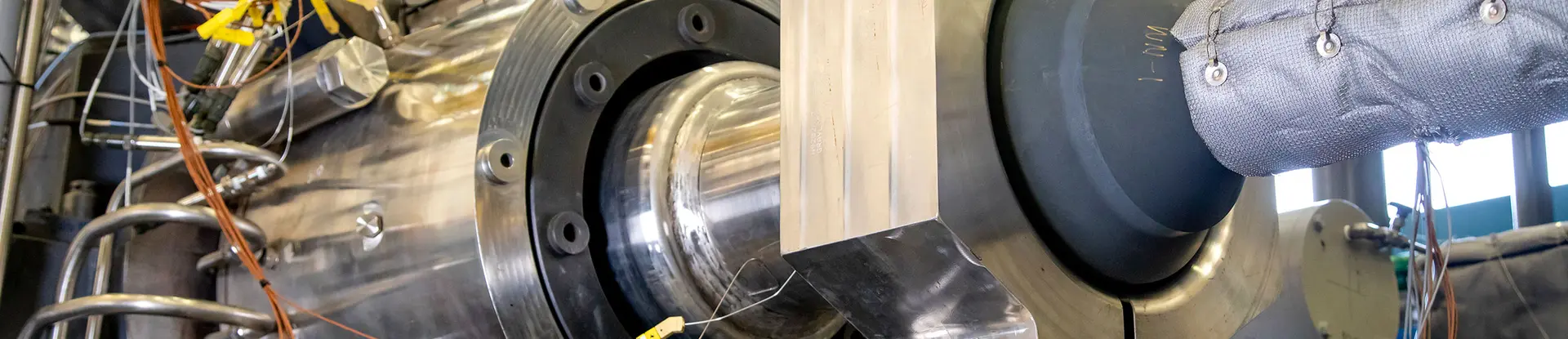

Image

The compander was created for a 10 MW-scale concentrated solar power supercritical carbon dioxide plant application. It converts thermal energy from a heat generation source, such as sunlight, to electrical energy.

LP: So what are some current applications for sCO2? How is it used?

TA: So some of sCO2's earliest commercial applications actually are in heat pumps for refrigeration applications. sCO2 has a much lower global warming potential than some of the refrigerants that are used in existing commercial heat pumps, so that's taken over actually in Asia and Europe and may be a future fluid for heat pumps here in the US. But for power cycles, sCO2 is really just again, it's useful for converting heat into electric power, so there's a lot of potential applications.

It's one of the things that's pretty exciting about it. You can take heat from concentrating solar power, from nuclear reactors, from waste heat, from other processes like other power generators or industrial processes, can even use geothermal heat. And so there's a lot of areas for sCO2 to be applied to. There are commercial pilots announced for power generation systems, and those are in concentrating solar power and in gas turbine waste heat recovery.

LP: All right. And there are even some applications that our listeners might be more familiar with, some everyday uses. So tell us a little bit about sCO2 applications for decaffeinating our drinks and in dry cleaning.

TA: I'm going to point this one to Jason. Jason, do you want to talk about that?

JW: Yeah, sure. So I'm not sure how often it's used as a dry cleaning fluid, although I've heard that it is. But it is very common in the food and beverage industry. I know it's used for flavor extraction in Jelly Bellys®. How do they get the popcorn flavor in the jelly bean, for example? All the caffeinated drinks that you buy that aren't naturally caffeinated, such as energy drinks and soft drinks, often get their caffeine from coffee beans that are extracted with CO2. And it's relatively simple. They pressurize the fluid up into the supercritical regime, which makes it act like a solvent. And then the oils seep out of the compound that you're trying to extract from. And then whenever you depressurize the CO2, all you're left with is the oily residue.

LP: So there we go. We're solving mysteries here. So the Jelly Bellys get their popcorn flavor with the help of sCO2. Good to know. Thank you. So at SwRI, we have built a facility to demonstrate and test sCO2 as the working fluid in power system components. Now, since our last discussion in August 2020, construction has been completed on the supercritical transformational electric power, or STEP, pilot plant. So what is the latest on the STEP pilot plant, and what is happening there currently?

TA: Yeah. The STEP pilot plant is a really exciting project here. It's the largest of all the projects that we've done with supercritical CO2. And really, its goal as a project is to take the many projects that have predated it, which have been really small systems or projects focused on developing different components that go into the power cycle, like different machines or heat exchangers, and we're putting it all together for the first time at conditions that are realistic of a power plant and scalable to very large power plants. So that's a pilot scale power plant that's on SwRI's campus. It's actually tied into our grid behind the meter, and we're going to run 10 megawatt scale power production here on-site.

Like you said, we talked about that in 2020 and a lot has happened since. So right now, the building has been completed since 2020. And the high bay is getting really full. A lot of the major components have arrived. We've installed the large heaters and coolers that are associated with the system. Some of the compressor systems are all they've arrived. They're installed. And we're just taking the installation of some of the last major heat exchangers and a first-of-a-kind turbine for the system. So we're finishing those installation tasks. And then we're starting the early commissioning tasks where we're going to go through system-by-system, make sure each component works individually before we try to operate them all together.

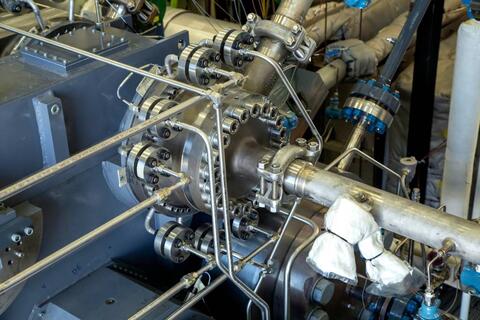

Image

The SwRI compander development team and Hanwha representatives accepted the R&D 100 Award at an awards banquet in Coronado, CA on November 17. From left to right: Rob Pelton, Tim Allison, Jason Wilkes, WonHyuk Yang (Hanwha), Natalie Smith, Chris Kulhanek, Thomas Revak.

LP: When do you expect testing to start?

TA: So some of those commissioning tasks are testing. They're just testing each component, and those will happen within the next really, a few weeks. But then as we work towards finishing the component level testing and doing full, integrated system testing, that's going to happen about a year from now, so in the second half of 2023.

LP: OK. So this is a question that came up on episode 22 as well. Could sCO2 electricity power our homes one day? Is that the goal? Are we closer to getting there?

TA: Yeah, I think that really is a large part of the goal. We do think that sCO2 revolutionizes power generation for many different technologies. So as we feed renewables into the grid, concentrating solar power plants using sCO2 might be a part of that mix. sCO2, when we're doing carbon capture, or even sCO2 from other sources, like nuclear, can make very large power plants, at the thousands of megawatt scale, which is comparable to today's largest power plants. And so that could all go into the energy mix that powers our homes.

The near commercial way that sCO2 will feed into our homes is through several commercial pilots. And these are smaller scale, not thousands of megawatts but tens of megawatts. And there are several pilots there. So there's a waste heat recovery system, there's a concentrating solar power system, and there's a geothermal system actually under development. And all those could end up on the grid and feed power to our homes.

LP: All right. So, Jason, turning to you now. Let's talk about the award-winning compounder. So you led the development of this technology and collaboration with Hanwha, headquartered in South Korea, and with the support of the US Department of Energy, Office of Energy Efficiency and Renewable Efficiency. So we also want to recognize the Hanwha team as well, Dr. Karl Wygant, Rob Pelton, and Jon Bygrave contributed to the compounder development. Did I say those names right?

JW: That is correct.

LP: OK. So this equipment converts heat, like sunlight, into electricity and it uses sCO2 to do that. So tell us more about the compounder. What does it do? How does it work?

JW: So the compounder is like many other traditional machinery solutions. It's different. Unlike a typical steam cycle is that it's based around one large gearbox, so there's not several compressors and expanders that sit on their own trains. They all hang off of a large gearbox, in this case, a 12-foot gearbox that's very substantial in size. So some of the pinions are compressing. Some of the pinions or expanding. So it's kind of like your IC engine in your car, which is both compressing and expanding the fluid within the same machine. So that's a little bit how it's different. It gives you a lot of flexibility. In the concentrated solar power system, the way that it would work is that sunlight would hit some media that would charge a storage tank and that storage tank could be several gigawatt hours of storage. Then you would pass that thermal fluid through a heat exchanger into the power cycle. So that's why it's different than a photovoltaic cell, which just produces sunlight whenever it's being hit by the sun. So it's a little bit more stable of a power solution and much more dispatchable and controllable on that end.

LP: So do we currently use photovoltaic cells like, let's say, in solar panels on our roof? Is that

JW: Correct, that would be the traditional panel that everybody has on their roof. They produce power when the sun is shining and you have to use it whenever the sun's shining.

LP: OK. So this is a little you just explained how it's different. And it doesn't just use sunlight. It can also use other forms of heat. Can you tell us about the other forms of heat it can use?

JW: Yeah. So once the energy is stored in the form of heat, any power cycle can effectively convert it to power if it works thermodynamically. In this case, between 500 Celsius and 700 Celsius, CO2 is a very, very good working fluid for that purpose. We use organic refrigerants or organic fluids. For lower temperature cycles, we use steam. That's the incumbent technology that we've used for the last 50 to 100 years. And they all work very, very similarly in that they compress, heat, expand, and then cool a working fluid.

LP: OK. So tell us what makes it clean energy technology. How does it reduce carbon emissions?

JW: I think clean energy technology is it's slightly misleading. At the end of the day, what a clean energy technology is is simply a technology that's competitive with non-clean energy technologies. And we're not going to just convert the entire world over to supercritical CO2. It won't be entirely solar cells. It won't be entirely wind. It's going to be a system of power generation methods that work together, including energy storage and other type of mechanisms. So the reason that this innovation is significant is that it makes a step towards concentrated solar power, which is available in a large portion of the world, a little bit more viable in comparison to running a gas turbine. As carbon emission taxes are levied against incumbent technologies, what we're going to find is that those are more expensive. And naturally, the other technologies will have a better position to compete with them. So this just goes a step in that direction.

LP: So maybe "cleaner energy technology" might be a little more accurate? It's cleaner than what we currently are using on a daily basis.

JW: It can be, yes.

LP: Can be. OK. Great. So

TA: The only thing I'll add to what Jason says is there is a variant of sCO2 power cycles where you're doing combustion and you do combustion in the power cycle. So it's at very high pressure supercritical conditions, and that allows you to use a fossil fuel. When you combust it, it produces more CO2 in water. And then you can capture that CO2 directly. It's already at conditions you need to run it through a pipeline and sequester it, so that's effectively a zero emission type power cycle.

LP: So, Jason, you've touched on this a little bit already, but if you could go through it again for us. So how does the compounder sCO2 technology compare to the conventional equipment powered by the steam cycle?

JW: That's a really good question, Lisa. In the early stages of any research and development technology, it's very, very challenging to forecast the cost of the end product and how many units will be in service. That's particularly challenging when inflation and supply chain challenges are making it more difficult to make a unit.

I think, in terms of levelized cost of electricity, is basically a way of saying, how much money does it take right now in order to make that energy per kilowatt, for example? It shows that it can be competitive with existing technologies, but what that requires is an adoption of the technology and for manufacturers to be making these by the 10s and 20s and 100s as opposed to making one unit, working with a supplier for one unit. That's obviously more expensive. So it's forecasted to be competitive with steam turbine technology at the current time.

There's other benefits as well. For example, a steam turbine takes about a day to warm up. As we're introducing more renewables on the grid, it becomes more challenging to manage the grid and to adapt our resources, like nuclear and coal, to ramp up at the rates that are needed in order to provide power when the sun's not shining or the wind's not blowing. So because these systems are much more compact, they also provide an economic advantage in that they can be spooled up quicker and run from zero power to full power at a much quicker rate than a conventional steam turbine would be able to run.

LP: OK. So the compounder is a mix of two different types of equipment. What are those two different machines? And tell us about your process to develop the compounder.

TA: Yeah. So I think you're probably referring to compressors and expanders or--

LP: There we go, yeah. That's it.

TA: They're conventional turbomachinery pieces. They're used in turbochargers in our car. I mean, a turbocharger in any vehicle nowadays is basically a radial compressor and a radial expander. That's the exact same technology that we're utilizing. However, it's at a much higher pressure and a much higher temperature. Well, maybe not a higher temperature, but it's a much higher pressure than would be used in a turbocharger. So it's got its own unique set of challenges for the design.

So there's multiple things in designing turbomachinery. We start with a cycle design. And the bottom line is, does it actually make sense according to the laws of thermodynamics? You assume some efficiencies. You assume some sizes. And that tells you what power you get, how effectively you'll convert it. Then you have to design the turbomachinery stages. How big is the impeller wheel? How big is the expander wheel?

And then the real challenge is, how do you make it work? How do you support the shaft as it's spinning at 18,000 RPM? How do you contain 4,000 PSI when it's basically making the metal glow red? These are the real challenges that we've learned to excel at within our department, in our section, and in making this technology viable. Because it's very, very similar to the power density that's in a rocket engine. The only difference is that a rocket engine needs to last 10 seconds and most of our designs have to last 100,000 hours.

LP: All right. Big difference there. So why is the compounder revolutionary? What makes it a groundbreaking technology?

JW: So I think the compounder is revolutionary in that it's one of the first few implementations of a type of technology. It showed a very successful test. I would also point out that our sunshot expander, that was developed by Dr. Jeffrey Moore about six years ago, it was the expansion part of this. And it aims at a different technology area, but both are very, very stringent in their requirements. So I mean, in an integrally geared frame, it's about the highest temperature and pressure combination that's ever been tested. It's about the highest pressure dry gas seal ever utilized. So there's a lot of firsts on the program that make it very, very unlikely to succeed at the start and very, very empowering that it did succeed at the end.

TA: Thanks, Jason. I'm going to chime in, too. Just from a customer's point of view, we've had a lot of talks with folks that want to put a sCO2-based power system in for a waste heat recovery system, for example. And some of the things that they really like about a compounder-based sCO2 power system is that it incorporates all these machines onto one big gearbox, so it's very compact and modular. You can put the whole compounder plus its associated heat exchangers and piping can be packaged really compactly into a modular skid. And that's groundbreaking, just for the ease of use of getting a high-efficiency power system into a commercial site. Using CO2 has other advantages over the other options they have for a system like that. If they're using steam or an organic fluid, they basically have to run a chemical plant on-site. The steam chemistry has to be managed. There has to be freeze protection for steam systems.

Organic fluids, you have to have makeup supplies, and there's hazards associated with organic fluids. So CO2 is kind of really the best candidate for them, and it's groundbreaking because CO2 doesn't freeze at ambient conditions. CO2 doesn't involve a lot of chemistry. You just have to charge it with an initial charge of CO2. So they see a lot of groundbreaking benefits from a compounder-based sCO2 system.

LP: All right. And beyond clients and beyond SwRI saying that this is groundbreaking and revolutionary, you just had a major recognition for this technology. The R&D 100 Awards are a huge deal in the tech world. For our listeners not familiar with the competition, it started in 1963 to honor the most significant innovations of the year and the awards are known as the "Oscars of Innovation." So with the compounder's win, this makes 51 R&D 100 Awards for SwRI. So, guys, thoughts on winning this award. How does that feel?

JW: Yeah. This is Jason. I think it's a recognition of the hard work and the effort that my team put in and obviously feels very good to be recognized. I think a lot of the technologies that we work on are so early stage within our department that it's not the commissioning of a unit that powers a bunch of people's homes. It's the technology that will power people's homes in 20 or 30 years. So I think it's great from that side, and it's been a team effort all the way through.

TA: Yeah. I'll also chime in. Beyond the team's accomplishments, which I really think the award represents, I think that it's also a leap forward for the technology to get that kind of recognition from a broader R&D community. I think it shows that sCO2 is making strides towards nearer-term implementation. And there's recognition from the research community about the importance of these transformational power systems.

LP: So tell us about that moment that you got the call or read the email that you won. Is it kind of like a it's got to be a celebratory moment. All these years of work and to get a big award like this has got to be has got to feel fulfilling. So tell us about that moment. Who got the news first?

JW: I think our communication specialist that applied for the award. He's the one that received that notification and he let us know. I obviously let our clients know. And, yeah, I think it made them feel very good. I think it was neat. I missed a number of dinners with my family to develop this machine in the sacrifice in time and effort that it took for every teammate. So, yeah, it's not an individual accomplishment.

TA: I think we both got the email at the same time, so I don't know who saw it first.

JW: So, actually, it was pretty funny. But Tim was in a meeting, and I think he was talking about another program that was in some distress. And it was a very serious conversation. And I kind of like I sort of interrupted and Tim was like, can't you see I'm in a very important meeting? I was like, we won. And so Tim was glad. It was sort of an awkward moment.

LP: Yeah. It was great news, right? You were the bearer of good news. So every year, we enter several of our technologies and we come back sometimes with multiple awards. But this was our one and only submission this year and our big win for the year for your team and for the institute. So I think it was great news for all of us.

JW: Well, thank you.

LP: Is the compounder in use now? How is it being used, if it is?

JW: Yeah. So the compounder was developed under the direction of a DOE program. Once we spent the budget and met the milestones for the DOE program, we have continued the development of the compounder. Gas turbines were invented 120 years ago, and we're still doing research and development and testing on them today. So this is the only version of the compounder that exists in physical form. And so my client that developed the compounder, Hanwha Power Systems, is continuing to test and validate the machine and its performance.

LP: OK. And

TA: Yeah.

LP: Oh, go ahead.

TA: Yeah, this is Tim. We actually also just received another DOE award on developing and testing kind of add-on or supplementary components to the compounder, special guide vanes that help it operate at different off-design conditions better. So we're continuing the development of technologies to make it even better.

LP: With the new recognitions, new grant money coming in to expand it, what do you envision for the future of the compounder and what industries could it be most useful?

JW: Yes. I'll answer that, Lisa. I think the main answer is that CO2 right now is being discussed, not only as a power cycle but in another of in very many other aspects. So we're talking about putting CO2 in pipelines across the United States for sequestration purposes. That brings a bunch of challenges in terms of how it's managed, how it comes out of the ground, multi-phase studies. How does it actually go into the ground? Currently, we only really pull stuff out of the ground, so we don't typically put stuff back into the ground. So there's a lot of challenges that accompany that topic as well as other technology that uses CO2. So our current plan and as we were working with the Department of Energy is to continue to use this asset to drive CO2 experiments for expansion, for combustion testing. We've got an oxy combustion test that's coming up, where we will be putting natural gas and oxygen in the high-pressure CO2. That will be driven by the compounder. So there's a number of different technologies where it can continue to support. It occupies a huge footprint in the lab, and we need to find uses for it.

LP: Other than the compounder, are there other sCO2 technologies in the works at SwRI? What can you talk about today?

TA: So there are several different kind of exciting alternate pathways that we're developing that focus on really different areas, different heat source temperatures or different size ranges, than the compounder might address. We've been doing a lot of work on very low-grade heat recovery and heat conversion to power using supercritical CO2. So we actually got an SwRI internal research project completed that focused on what we call "natural convection loops," so using CO2 that circulates itself when you get the right temperatures involved because of its buoyancy. And so that's something we could use to have an sCO2 power geothermal generation system. And we've done that internal research and are working with clients to develop systems for that.

We're also working on sCO2 for waste heat recovery but at a very small scale. This is in partnership with the Powertrain Engineering Division at SwRI and that involves if you think of a heavy-duty truck, it's got a big engine that's running. It wastes a lot of energy in pumping waste heat out the exhaust pipe. So if we can put a very small supercritical CO2 system to gather some of that and create additional electricity, that really improves the overall engine efficiency. That's so small that it's not a compounder is too big of a solution for it. Compounder will go down to the megawatt range but not the kilowatt range that we need for a vehicle. So we're developing technology like a reciprocating power block using supercritical CO2 that could work in that application. And then Jason mentioned this as another use for the compounder. It's going to run and provide flow for a test loop, where we'll do combustion in CO2 at supercritical conditions. And that allows really high-grade heat and high-efficiency power cycles with that inherent carbon capture. So we'll be developing a new oxy combustion technology that runs with the compounder.

LP: All right. Excited to see what you're developing next. Tim, Jason, congratulations to your team on the R&D 100 Award for the compounder. Really important technology and work as you look at ways that sCO2 can reduce carbon emissions. So thank you both for being here today to help us understand the many possibilities of supercritical carbon dioxide and telling us all about the award-winning compounder.

TA: Thank you very much, Lisa. We appreciate your time.

JW: Yeah. Thanks for having us.

And thank you to our listeners for learning along with us today. You can hear all of our Technology Today episodes and see photos and complete transcripts at podcast.swri.org. Remember to share our podcast and subscribe on your favorite podcast platform.

Want to see what else we're up to? Connect with Southwest Research Institute on Facebook, Instagram, Twitter, LinkedIn, and YouTube. Check out the Technology Today Magazine at technologytoday.swri.org. And now is a great time to become an SwRI problem solver. Visit our career page at SwRI.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening.

[MUSIC PLAYING]

Southwest Research Institute is a leader in advanced power systems, including the design, analysis, prototype fabrication, and testing of turbomachinery such as gas turbines, compressors, pumps, wind turbines, and motors from kW-scale to utility-scale. With more than 50 years of experience assessing and improving power generation equipment, SwRI is also a leading developer of cutting-edge power generation technology.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.