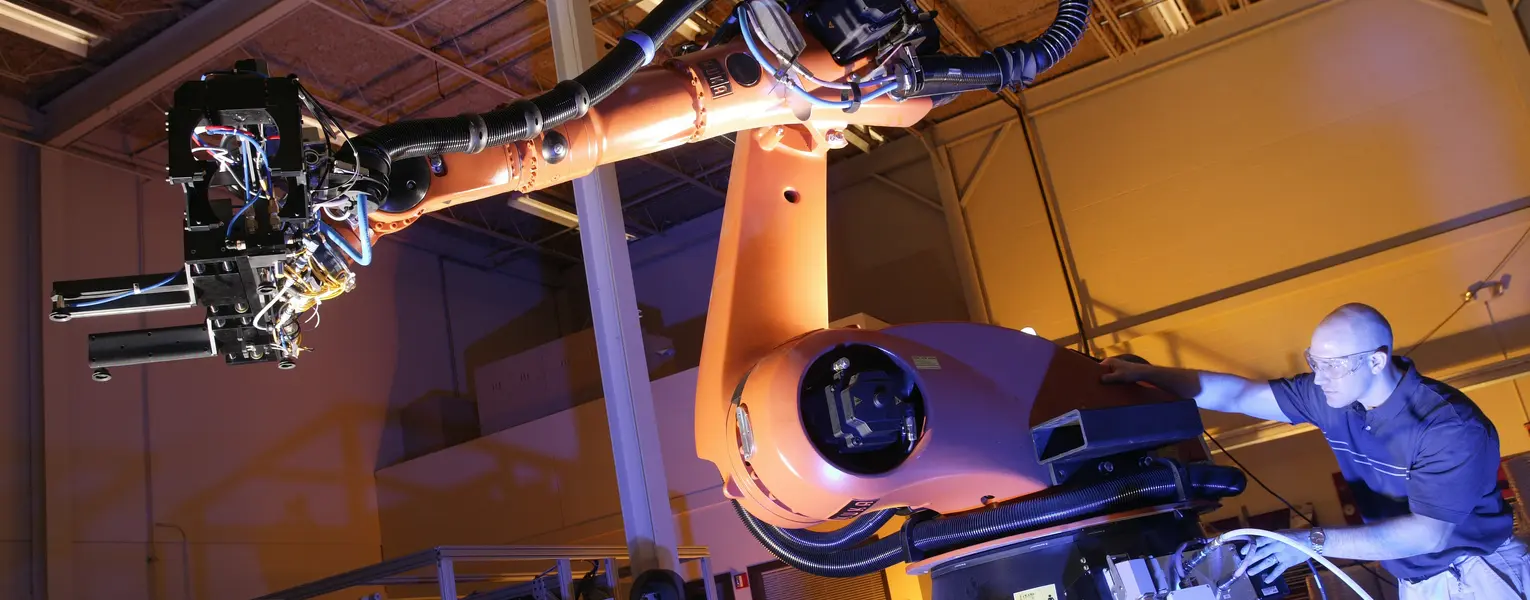

Revolutionizing Robotic Welding for Manufacturing

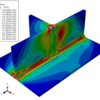

Algorithms enhance weld sequence optimization to minimize distortion and residual stress

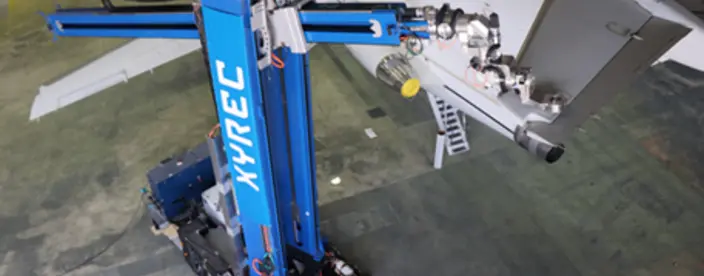

Accuracy and efficiency are becoming ever more critical in robotic welding as designers of structures seek to push the limit in design and the what manufacturing processes can deliver. As manufacturers seek to expand robotics automation into shipbuilding and heavy industry, engineers on both the product design and manufacturing sides need advanced tools to predict weld distortion and stress, which can affect structural integrity.