Supercritical carbon dioxide (sCO2) is carbon dioxide held above a critical temperature and pressure, which causes it to act like a gas while having the density of a liquid. It’s also nontoxic and nonflammable, having been used in dry cleaning processes as well as to decaffeinate coffee. Its supercritical state makes sCO2 a highly efficient fluid to generate power because small changes in temperature or pressure cause significant shifts in its density. This same characteristic makes turbomachinery design challenging.

Southwest Research Institute is a leader in sCO2 power cycles, having received more than $120 million in funding to demonstrate the feasibility of the power cycle in addition to developing machinery to support it and addressing any further challenges that may arise from the widespread adoption of the technology. SwRI participates in the biannual Supercritical CO2 Power Cycles Symposium to advance sCO2 technology.

Supercritical CO2 Pilot Plant

SwRI is collaborating with a team led by GTI Energy and sponsored by the U.S. Department of Energy Office of Fossil Energy and Carbon Management to design, build, and operate a 10-MWe (megawatt electric) supercritical CO2 pilot plant for demonstrating supercritical carbon dioxide (sCO2) power cycles at our headquarters in San Antonio. Visit the Supercritical Transformational Electric Power Pilot Plant (STEP) Demo project website to learn more. The research team is striving to make the idea of cleaner, cheaper power a reality by advancing power plant components that are smaller and therefore more cost-effective. sCO2 power cycles also offer the advantage of burning far fewer fossil fuels, reducing the impact on the environment.

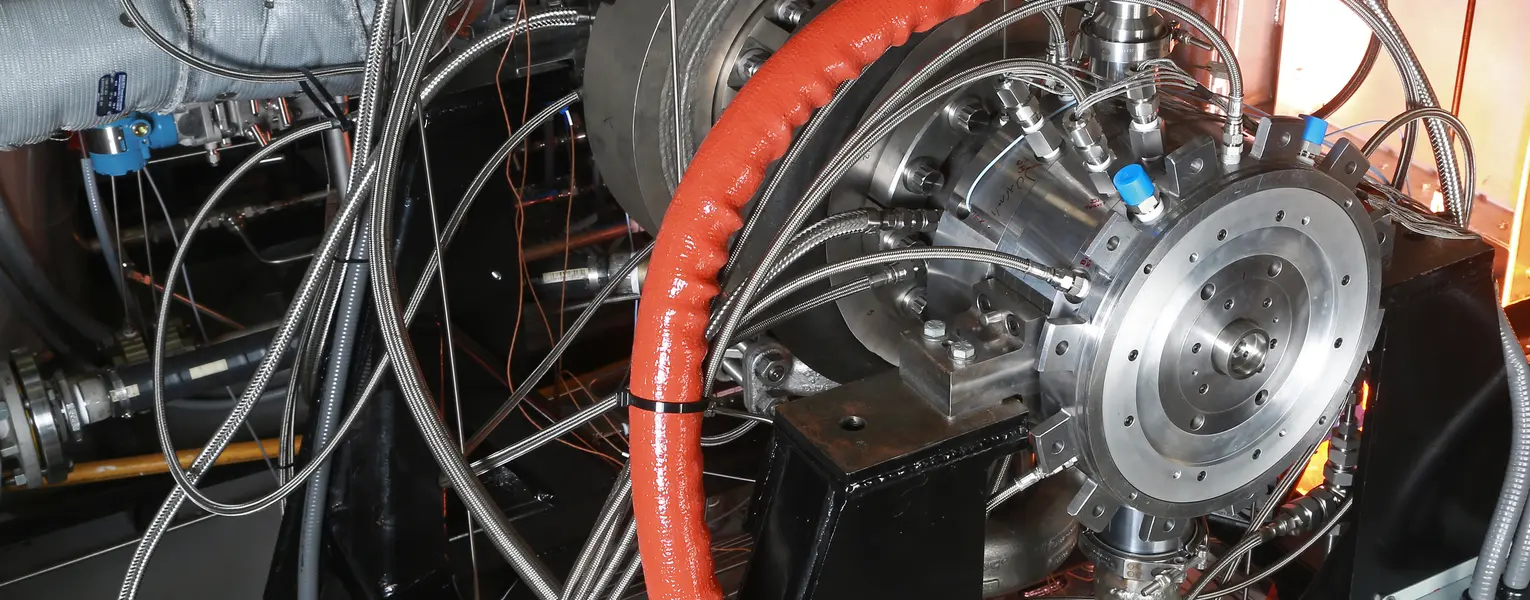

The Institute is also home to the highest temperature sCO2 turbine in the world, which will eventually be incorporated into the STEP Demo pilot plant. Developed with the support of the U.S. Department of Energy Solar Energy Technologies Office, the full 10-megawatt turbine is the size of a desk and yields the highest power density of any industrial turbine, rivaled only by the turbopumps used on the space shuttle engines. This small but powerful turbine can withstand the tough operating conditions of concentrated solar power (CSP) plants and is highly scalable, to as much as 450 MW. This technology could result in a two to four percent efficiency increase for state-of-the-art fossil fuel-fired steam plants, reducing CO2 emissions equivalent to 14 million cars.

Benefits of sCO2 Power Cycles

Electricity is generated by converting resources such as hydrostatic pressure, solar energy, coal, natural gas, or wind into electrical currents that result in the power we use in our daily lives. Most power plants in the U.S. are thermal conversion plants.

Most natural gas plants begin the process of generating power by first combusting natural gas with compressed air, which results in hot gas pressure that turns a turbine. This is typically an open cycle and is the principle behind both aircraft and land-based gas turbines. For power generation, the spinning turbine connects to a generator, which in turn spins wire coils to create electricity. This is known as a Brayton cycle, whereas plants that utilize steam in a closed-loop are utilizing the Rankine cycle.

sCO2 power cycles replace water or steam with supercritical carbon dioxide. Benefits of this process include:

- The supercritical state of sCO2 makes it a highly efficient fluid to generate power because small changes in temperature or pressure cause significant shifts in its density. Replacing steam or air with sCO2 as a thermal medium increases efficiency by as much as 10 percent.

- sCO2 equipment is one-tenth the size of conventional power plant components, providing the potential to shrink the environmental footprint as well as the construction cost of any new facilities, which will be significantly smaller than today’s power plants. For example, a desk-sized sCO2 turbine could power 10,000 homes.

- sCO2 is a non-toxic working fluid with the ability to be applied to concentrated solar power, natural gas, coal, biomass, geothermal energy, nuclear energy, ship-board propulsion, and waste heat recovery.

Related Services

- Supercritical Transformational Electric Power Pilot Plant

- Supercritical CO2 Power Cycles Symposium

- Advanced Power Systems

- Carbon Dioxide Pipeline Technologies

- Concentrating Solar Power (CSP) Energy Storage

- Thermal, Mechanical & Chemical Energy Storage

- Decarbonization Technology Services

- Machinery

- Turbomachinery Design & Testing