Background

Figure 1: Engine piston rings that are being targeted for possible fuel economy gains using low-friction coatings.

Figure 1: Engine piston rings that are being targeted for possible fuel economy gains using low-friction coatings. Aggressive greenhouse gas and fuel economy regulations require that automakers continually improve the fuel economy of new vehicles. Consequently, automakers are requiring their suppliers to develop advanced vehicle hardware that contributes to these fuel economy goals. The objective of this research is to investigate the possible fuel economy gains that can be achieved using low-friction coatings on engine piston rings, as shown in Figure 1. For this program, a high precision measurement technique is used to determine a vehicle’s fuel economy both before and after an SwRI-developed low-friction coating is applied to piston rings. This measurement technique yields results that relate directly to global fuel economy regulations without the need to extrapolate from bench-style friction testing.

Approach

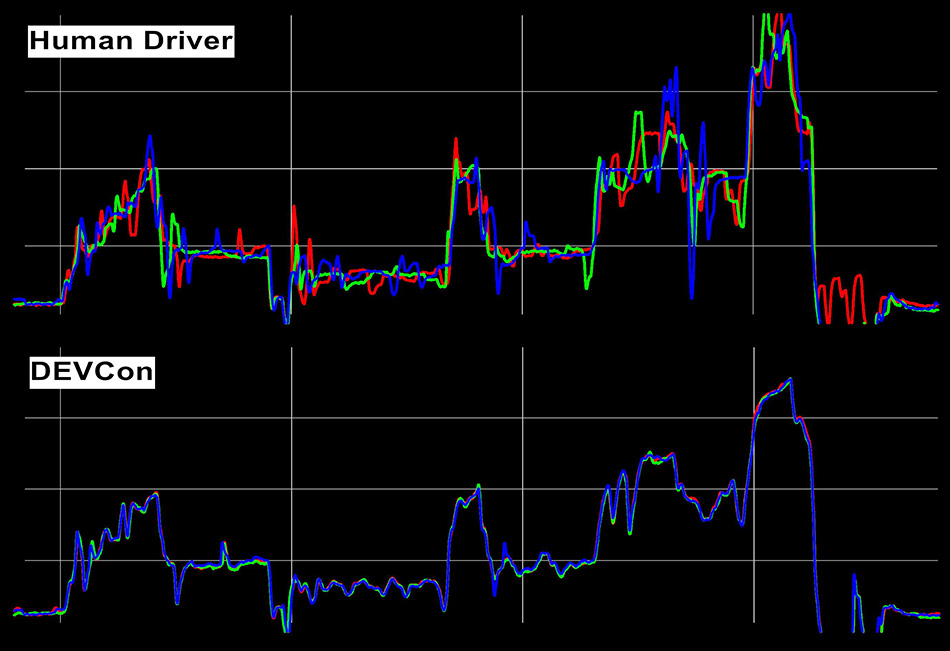

The technique for evaluating the low-friction coating is the implementation of SwRI’s Direct Electronic Vehicle Control (DEVCon™) system combined with a high precision chassis dynamometer. DEVCon is used to apply an electronic accelerator pedal position (APP) signal directly to the vehicle’s engine control unit (ECU) and eliminates the variation normally introduced by a human driver. Figure 2 shows an example of continuous fluel flow that was measured from three repeat tests using both a human driver and DEVCon for vehicle control.

Figure 2. An example of continuous fuel flow that was measured from three repeat tests using both a human driver and DEVCon for vehicle control.

Accomplishments

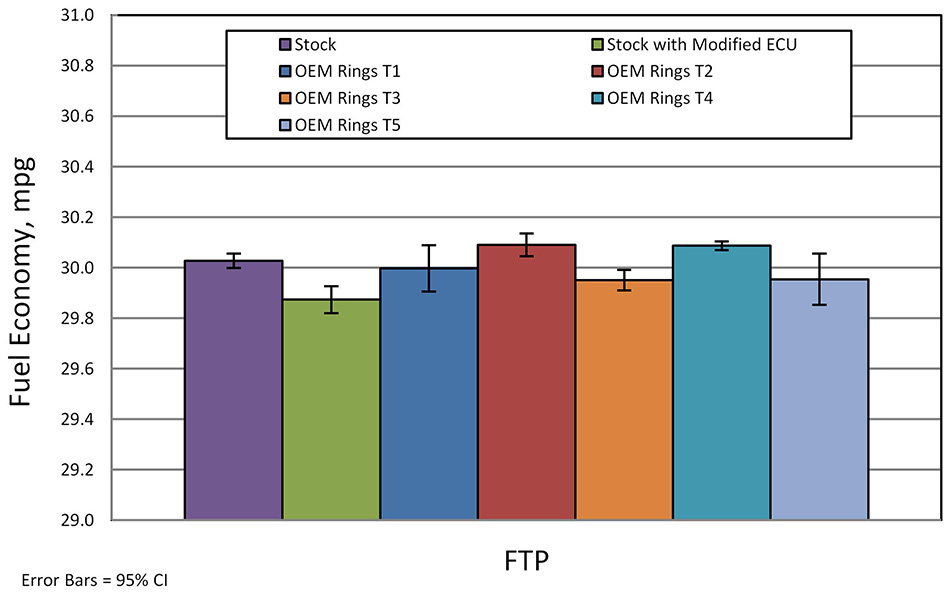

The test vehicle’s fuel economy has been measured from multiple vehicle configurations using the Federal Test Procedure (FTP-75) and Highway Fuel Economy Test (HwFET) vehicle certification cycles. The first three baseline configurations were used to establish a fuel economy datum and to measure the influence of the piston ring installation process. Baseline configurations were used to bracket tests that used coated piston rings and to monitor baseline stability through the program. Figure 3 shows the excellent fuel economy stability observed for all baseline configurations. Specifically, the stability of this baseline data set would allow a small fuel economy improvement of only 0.64 percent to be statistically validated.

Figure 3: Excellent fuel economy stability observed for all baseline configurations.

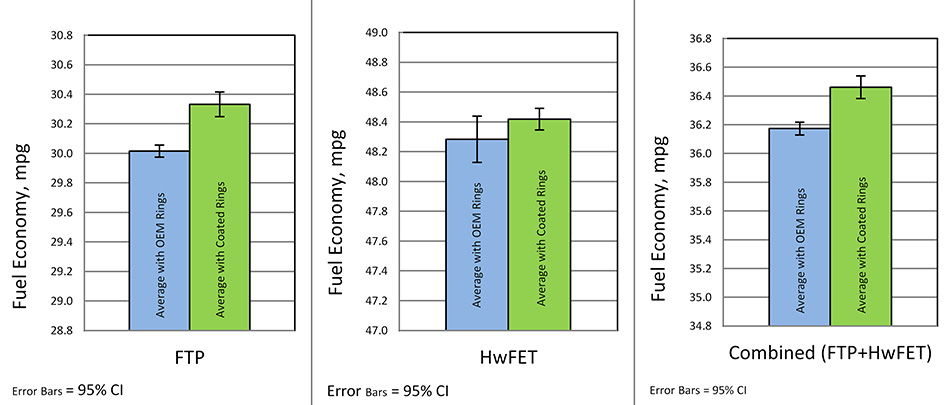

After determining that baseline stability was acceptable, piston rings coated with 25 mm of a low-friction TiSiCN nanocomposite material were installed in the engine to investigate the fuel economy effects of the coating. An average fuel economy improvement of 0.79 percent was measured over the Combined Cycle (FTP + HwFET) for configurations using the coated piston rings compared to baseline (OEM) rings. Figure 4 shows the average fuel economy from coated and baseline configurations. Additional testing is under way to fully validate the findings.

Figure 4: Average fuel economy from coated and baseline configurations.