Background

The primary objective of the project was to develop and validate an approach for measuring the heat release rate (HRR) versus time curve for room fire tests conducted in building 166 based on a combination of inverse compartment fire modeling and oxygen consumption calorimetry. More specifically, the intent was to demonstrate that SwRI has (or can develop) the capability to perform room fire tests in which peak and steady HRRs can be measured up to 15 MW and 8 MW, respectively.

Building 166 measures 40 x 60 x 36 ft. and is primarily used for 15 MW jet fire tests, for which oxygen consumption HRR measurements are not required. The fire effluents generated in this building are extracted through a vent in the back wall above a false ceiling, which is at 30 ft. above the floor. The vent is connected to a quench, a pollution abatement system, a fan with a capacity of extracting fire effluents at a rate of 35,000 SCFM, and a stack.

Approach

The approach for the project consisted of the following tasks:

- Install the necessary probes and instrumentation in the exhaust duct so that HRR can be measured using oxygen consumption calorimetry

- Perform a calibration test with a 1,500 kW propane burner (the highest diffusion flame gas burner available in the department) placed on the floor of building 166, directly below the 6-ft wide opening in the false ceiling in the back of the building where the exhaust duct connects to the building

- Use the data obtained in #2 to validate Fire Dynamics Simulator (FDS), a CFD code developed at NIST specifically to simulate fires

- Use FDS to determine how the exhaust configuration in building 166 can be modified to determine the maximum HRR that can be measured before the smoke starts to spill and is no longer completely collected

Accomplishments

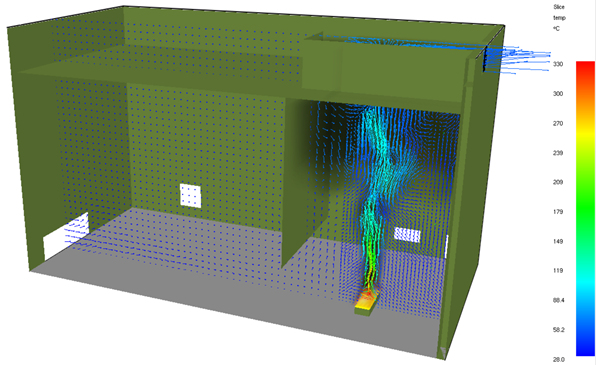

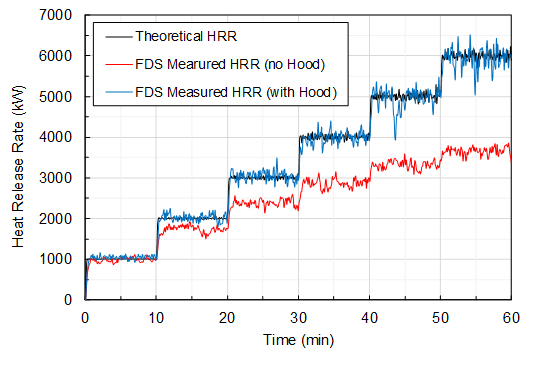

The proposed approach to use inverse modeling turned out to be impractical due to the time needed to complete the necessary iterations of CFD calculations. However, the calibration test allowed us to validate FDS and demonstrate that HRRs up to 15 MW can be measured accurately by installing a hood of specific dimensions in building 166. The CFD simulations were used to determine the minimum dimensions (width, depth, and height above the floor) needed to ensure that all combustion products are collected during peak burning, while minimizing flattening of the peak HRR. Fig. 1 shows FDS simulation of 6 MW fire with hood down to 16 ft. above the floor. Fig. 2 compares the FDS predictions of the measured HRR without hood (present configuration) and with hood.

Figure 1: FDS simulation of 6 MW fire with hood down to 16 ft. above the floor.

Figure 2: Comparison of FDS measured HRR predictions without and with hood.