Background

Figure 1: Deposition of thick DLC coatings at the interior surfaces of a long pipe at SwRI.

Figure 1: Deposition of thick DLC coatings at the interior surfaces of a long pipe at SwRI. The oil and gas and petrochemical industries have a need for thick diamond-like carbon (DLC) coatings on the interior surface of long pipes to increase corrosion and erosion resistance. Using a plasma immersion ion deposition (PIID) process, SwRI has demonstrated that thick (>10 µm) DLC coatings can be deposited on the outer surfaces of components. The coatings typically have shown excellent wear and erosion resistance and also provide corrosion resistance in saltwater and CO2 environments, which are commonly seen in O&G fields. SwRI also has developed a PIID-based coating process by which a thin functional (hydrophobic) coating can be deposited on the interior surface of long pipes up to 80 ft. long to prevent hydrate from clogging the pipes. To date, however, SwRI has been unable to deposit thick DLC coatings (5-10 µm) for erosion/corrosion protection in long pipes. Therefore, the objective of the project is to develop a coating technology by which thick, wear and erosion and corrosion resistant DLC coatings can be deposited on the interior surface of long pipes.

Approach

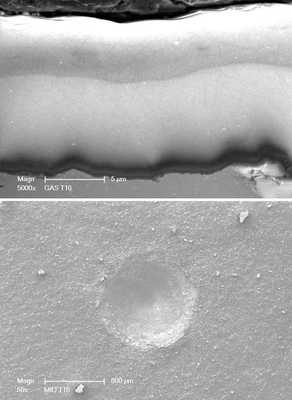

Figure 2: (top) Cross-sectional SEM micrograph of a thick DLC coating (14 μm) deposited on the interior surface of a 7 feet long stainless steel pipe (diameter of 4 inches). (bottom) HRC indentation performed on the surface of the coating which shows no coating delamination and cracking.

Figure 2: (top) Cross-sectional SEM micrograph of a thick DLC coating (14 μm) deposited on the interior surface of a 7 feet long stainless steel pipe (diameter of 4 inches). (bottom) HRC indentation performed on the surface of the coating which shows no coating delamination and cracking. Initial coating development was carried out on 7 ft. long pipes (4-inch diameter) to optimize key deposition parameters and power supply configurations. Stainless steel witness coupon samples were placed inside the pipe for characterization and process optimization purposes. The efforts were focused on developing a stable PIID process for obtaining high quality thick DLC coatings in long pipes. The corrosion resistance of the DLC coatings on coupon samples were evaluated using electrochemical impedance spectroscopy (EIS) tests, salt spray test, and scaling resistance test. After successfully depositing high quality thick DLC coating (5-10 µm) on coupon samples in 7 ft. long pipes, the coating process was transferred and demonstrated on large aspect ratio pipes (30 ft. long, 4-inch diameter).

Accomplishments

A new HC-PIID coating technology using combination of AC and pulsed DC power technologies has been successfully developed to coat the internal surface of long pipes with thick DLC coatings (up to 20 μm) with high deposition rate (2-3 μm/hr). The coating consists of an Al metal bond layer, a SiCx transition layer and a thick DLC layer. Overall, the thick DLC coatings on the internal surface of long pipes exhibit dense structure and good adhesion. The developed coating technology provides enhanced wear and erosion resistance of the internal surface of long pipes and improves their durability. The corrosion test of coupon samples sectioned off from the coated pipe in salt spray testing and electrochemical impedance testing showed that the thick DLC coatings on the internal surface of long pipes provides certain levels of corrosion resistance. The developed coating technology can be jointly applied with the previously commercialized hydrophobic thin films for long pipes to significantly improve the durability and performance in industrial working environment.