Background

SwRI’s Exhaust Composition Transient Operation Laboratory™ (ECTO-Lab™), generates a continuous exhaust flow through combustion of fuels and proprietary compounds, producing an exhaust gas composition that replicates the gaseous species created from the combustion of hydrocarbon (HC) fuel in an engine. The exhaust gas conditions are generated through independent, model-based controls and allow any combination of mass flow, temperature, HC concentration and speciation, oxides of nitrogen (NOx) concentration and speciation, water (H2O) and oxygen (O2) concentrations. Essentially, the ECTO-Lab functions as an exhaust gas simulation system to replicate the exhaust gas stream accurately and precisely from an infinite number of engines and combustion regimes.

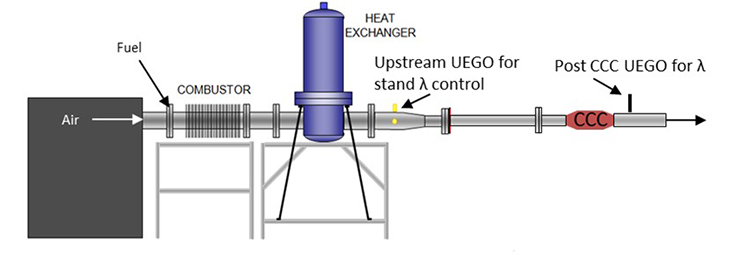

In the stoichiometric version of ECTO-Lab, it is SwRI’s standard procedure to use an upstream O2 sensor to ensure the stoichiometric feed gas into multiple catalyst units regardless of the distribution of each sample’s performance. While this is the preferred method of validating the Air/Fuel Ratio (AFR) for many clients, companies have demonstrated an interest in using a downstream O2 sensor placed after the Close-Coupled Catalyst (CCC). When the O2 sensors are used in this manner, the upstream sensor allows the controller to achieve rapid response under transient conditions, while the downstream O2 sensor is used to trim any long-term aging effects of the catalyst. An increasing frequency of lean/rich switching is required to maintain catalyst performance. This control mechanism requires downstream feedback from an oxygen sensor to track the changes in oxygen and hydrocarbon breakthrough [1] which will vary with time as oxygen storage decreases due to catalyst aging. [2]

Figure 1: Upstream and Downstream Post CCC Lambda Sensors

As this control configuration is typical of modern engines, it has the potential to better reflect the approaches used in engine-based aging while reducing aging costs through use of a burner system.

Approach

In summary, the ECTO-Lab AFR controller was coded to compare the readings from an upstream UEGO O2 sensor (λ sensor) to a downstream wide band O2 sensor. The lambda feedback adjusted the AFR when the downstream wide band sensor detected lean A/F, indicating that the catalyst has taken up oxygen. Once lean AFR was detected downstream, the burner’s combustion conditions were changed such that the AFR at the upstream sensor detected rich conditions until the downstream sensor reached rich conditions. The frequency of this change was coded such that it could increase as the time to reach lean downstream (i.e., catalyst saturates with O2) decreased due to catalyst aging effects. Two pairs of catalysts were aged for 100 h using a fuel cut cycle, one using the standard upstream O2 sensor and one using the dual O2 sensor controller. Oxygen storage capacity was used as the metric of comparison with measurements taken of degreened catalysts and aged catalysts. The oxygen storage from the catalysts aged using a dual sensor system was compared to a catalyst aged using a single upstream O2 sensor.

Accomplishments

A dual O2 sensor A/F ratio controller was successfully developed, enabling the stoichiometric gasoline burner to dither between lean and rich conditions during operation. Initial testing indicates that this lean/rich dithering influences the extent of aging of three-way catalysts, particularly the close-coupled catalyst when one is paired with a downstream underfloor catalyst. Indeed, catalysts aged with a single burner-out O2 sensor and no dithering exhibited a decrease in oxygen storage in the close-coupled catalyst. Catalysts aged using the dual O2 sensor controller did not experience comparable degradation of oxygen storage after 100 hours of aging. No increase in lean/rich switching frequency was observed while aging the test catalysts which is consistent with a lack of decrease in measured oxygen storage on the aged test catalysts.

[1] C. Steiner, V. Malashchuk, D. Kubinski, G. Hagen, and R. Moos, “Catalyst state diagnosis of three-way catalytic converters using di_erent resonance parameters—a microwave cavity perturbation study,” Sensors (Switzerland), vol. 19, no. 16, 2019, doi: 10.3390/s19163559.

[2] D. Rathod, M. A. Hoffman, and S. Onori, “Determining Three-Way Catalyst Age Using Differential Lambda Signal Response,” SAE Int. J. Engines, vol. 10, no. 3, 2017, doi: 10.4271/2017-01-0982.