BACKGROUND

A supply of clean water is crucial to the success or even feasibility of emergency response agencies and many military operations. In remote and disaster hit areas water supply from conventional resources is unavailable or logistically challenging. A means of harvesting water from ambient air would address these issues and reduce the dependency of clean water supply through conventional water resources. One such approach for atmospheric water harvesting (AWH) is to condense moisture from ambient air using a refrigeration system. However, this type of system becomes inefficient or even impractical in low humidity (<40% relative humidity) environments. A technological alternative to the refrigeration-based system for AWH is an adsorption- and desorption-based process using hygroscopic high surface area materials that capture water vapor from the air. Adsorption-based AWH technology can be standalone or be used to augment mechanical refrigeration by expanding the humidity range at which a system can operate. In an adsorption-based AWH system, once the adsorptive materials are saturated with water vapor, thermal energy can be added to the material to release the water vapor molecules and form higher humidity air that is more easily condensed. This approach for harvesting atmospheric water at low humidity has been successfully demonstrated at the lab scale producing milliliters of water per day, as documented in literature. The objective of this project was to use a fluidized bed approach to determine if adsorption-based AWH technology can effectively scale to a size that produces liters of water per day by reducing the cycle time and to assess the long-term water production performance.

APPROACH

Several steps were executed to determine the scalability and performance of adsorption-based AWH. The first step was to review the literature to identify water vapor adsorbents that can be synthesized in a lab or are commercially available. Two adsorbents were shortlisted as potential candidates: Metal Organic Framework (MOF-303) and Silica Gel (SG) Desiccant. MOF-303 was synthesized by SwRI while SG was commercially procured. Static and dynamic adsorption tests were performed over these materials to determine their water uptake capacity per unit mass over a range of humidity and other operating conditions. MOF-303 can adsorb more water than SG per unit mass but its small particle size and fragile agglomerates (formed with binding to increase the particle size) made it impractical to use in a fluidized bed. Multiple small-scale fluidized bed dynamic tests were performed with SG (Figure 1) to study the effects of relative humidity, fluidization velocity, particle size, and SG mass on the water uptake capacity and adsorption-desorption cycle time. Next, based on the test data and empirical correlations, fluidized bed modeling was performed to estimate pressure drop, heating requirement, and sizing of the scaled-up prototype. Finally, a large-scale prototype was fabricated to demonstrate a closed-loop circulatory fluidized bed (CFB) concept for continuous water harvesting.

ACCOMPLISHMENTS

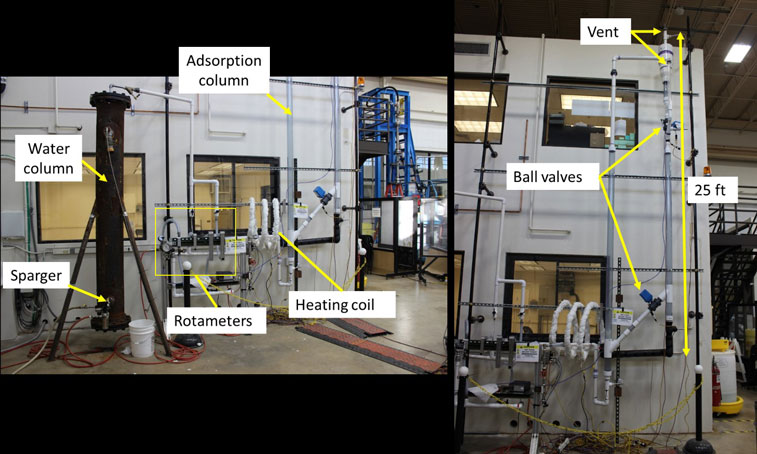

The objectives were achieved in this research program in that a novel, large-scale adsorption-based AWH prototype (Figure 2) was successfully designed, tested, and yielded nearly one liter per day of water production at 30% relative humidity which is approximately 800 times greater than what has been demonstrated in the literature at similar conditions. The data gathered from this prototype were used to verify scaling models for a fluidized bed AWH process, and it was demonstrated that stable, long-term water production could be attained using this design. Protocols for manufacturing MOFs that can be utilized in fluidized beds were also demonstrated in this project, as these materials have superior water uptake capacity thus yielding much higher quantities of water compared to silica gel. Lastly, the variables that dictate water production in a fluidized bed were characterized and several lessons learned and observations in the test program were documented that can be utilized to improve water production performance in future designs.

Currently, the researchers are presenting the results at conferences, investigating integrating this technology with commercially available refrigeration-based technology, and investigating the use of novel, low-cost hygroscopic materials provided by other research groups. The research was presented at the Department of Defense’s Operational Energy Innovation Symposium in Arlington, VA, in December 2022.

Figure 1: Small-scale fluidized bed tests with SG particles: Upwards gas flow in this image provides drag on the particles and levitates them within the flow resulting in a fluidized bed. Fluidized beds are utilized in this process to enhance heat and mass transfer. A change in color from blue (fully activated state) to pink (fully saturated) indicates completion of the water adsorption process.

Figure 2: Circulating fluidized bed large-scale prototype: These photographs show the overall layout and scale of the adsorption-based AWH prototype that yielded about one liter of water per day at 30% relative humidity inlet air.